Introduction to Distribution Transformers Design

Distribution Transformer Design plays a vital role in electrical power transmission and distribution systems. Among various transformer ratings, the 25KVA 11/0.415KV transformer holds significance in diverse applications due to its specific design and functionalities.

Design Considerations for 25KVA Distribution Transformers

When designing a 25KVA transformer, several crucial aspects need consideration. The voltage specifications, including the primary and secondary voltages (11KV/415V), determine the transformer’s performance and applicability in various setups. Design elements, such as core materials, winding configurations, and cooling methods, significantly impact the transformer’s efficiency and reliability.

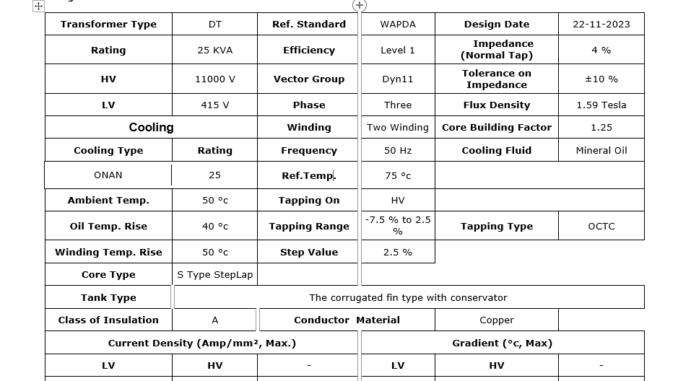

25KVA 11/0.415 Distribution Transformer Design Specification

| Transformer Type | DT | Ref. Standard | IEC-60076 | ||

| Rating | 25 KVA | Efficiency | Level 1 | Impedance (Normal Tap) | 4 % |

| HV | 11000 V | Vector Group | Dyn11 | Tolerance on Impedance | ±10 % |

| LV | 415 V | Phase | Three | Flux Density | 1.59 Tesla |

| Cooling | Winding | Two Winding | Core Building Factor | 1.25 | |

| Cooling Type | Rating | Frequency | 50 Hz | Cooling Fluid | Mineral Oil |

| ONAN 25KVA | Ref. Temp. | 75 °c | |||

| Ambient Temp. | 50 °c | Tapping On | HV | ||

| Oil Temp. Rise | 40 °c | Tapping Range | -7.5 % to 2.5 % | Tapping Type | OCTC |

| Winding Temp. Rise | 50 °c | Step Value | 2.5 % | ||

| Core Type | S Type StepLap | ||||

| Tank Type | The corrugated fin type with conservator | ||||

| Class of Insulation | A | Conductor Material | Copper | ||

| Current Density (Amp/mm², Max.) | Gradient (°c, Max) | ||||

| LV | HV | – | LV | HV | – |

| 2.8 | 2.8 | – | 20 | 20 | – |

Factors Affecting Transformer Design

The design process must accommodate load variations and characteristics to ensure optimal performance. Thermal considerations, including heat dissipation and insulation, influence the transformer’s durability and operational efficiency. Selecting the right materials, such as conductors and insulators, is pivotal in achieving desired electrical characteristics.

Download Transformer Design-1

Download Transformer Design-2

Download Transformer Design-3

Download Transformer Design-4

Download Transformer Design-5

Understanding 11/0.415KV Transformers

The 11/0.415KV voltage ratio signifies the transformation ratio between the primary and secondary sides. These transformers find applications in numerous industries, including commercial and residential setups, due to their adaptability and compatibility with standard power distribution systems.

Efficiency and Performance of 25KVA Transformers

Factors like core losses, copper losses, and stray losses influence efficiency in transformers. Evaluating performance parameters such as voltage regulation, load losses, and short-circuit withstand capability is crucial in assessing the overall effectiveness of a 25KVA transformer.

Optimization Techniques in Transformer Design

To enhance efficiency and performance, modern design methodologies incorporate advanced optimization techniques. These include utilizing high-grade magnetic materials, innovative cooling systems, and adopting computational tools for precise design simulations.

Quality Control and Testing in Transformer Manufacturing

Manufacturers adhere to stringent quality control measures and testing protocols to ensure transformer reliability and safety. Compliance with international standards ensures high-quality production, minimizes potential risks, and ensures optimal functionality.

Environmental Considerations in Transformer Design

Transformer design increasingly focuses on sustainability, employing eco-friendly materials and production processes. Adherence to environmental regulations and initiatives aims to reduce the ecological footprint associated with transformer manufacturing and operation.

Future Trends in Distribution Transformer Design

Technological advancements continue to shape the future of transformer design. Innovations such as smart grids, IoT integration, and advancements in material science are expected to revolutionise transformer functionalities, making them more efficient, reliable, and adaptable to evolving energy needs.

Conclusion

The design of 25KVA/11/0.415KV distribution transformers encompasses various intricate factors that determine their efficiency, reliability, and environmental impact. Embracing technological advancements and sustainable practises will pave the way for more efficient and eco-friendly transformer designs in the future.

FAQs

What does 25KVA denote in a transformer rating?

The rating denotes the apparent power capacity of the transformer, indicating its maximum output under specified conditions.

Why is voltage regulation important in transformers?

Voltage regulation ensures that the output voltage remains stable even under varying load conditions, ensuring consistent performance.

How do cooling methods affect transformer efficiency?

Efficient cooling methods help dissipate heat, preventing overheating and ensuring optimal performance and longevity of the transformer.

What are the key challenges in transformer design for future technologies?

Future challenges include integrating advanced technologies, meeting higher efficiency standards, and addressing environmental concerns without compromising performance.

Can distribution transformers be customised for specific applications?

Yes, manufacturers often customise transformers to meet specific voltage, load, and environmental requirements for different applications.

Leave a Reply