Describe about Solenoid

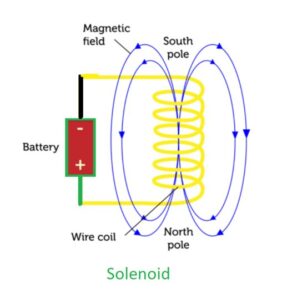

A solenoid is a long wire that has been twisted into the shape of a helix to help create a consistent magnetic field. If the turns are closer together, it might be seen as a circular loop. With an increase in length, a solenoid’s internal magnetic field becomes more uniform. A solenoid’s total magnetic field is equal to the sum of the magnetic fields generated at each of its turns. Since its length is significantly greater than the radius of its turns, a perfect solenoid has no outside fields and an even internal field.

What is solenoid mechanism?

There’s a decent probability that you’ve used many solenoids today. Every day, they assist you with starting your automobile, ringing your doorbell, and doing countless other tasks. But what exactly is a solenoid, and how does it operate?

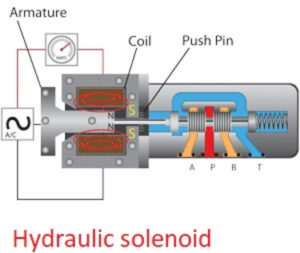

A solenoid works by generating an electromagnetic field around its moving core, or armature. The electromagnetic field causes the armature to move, and when it does, it opens and closes valves or switches, converting electrical energy into mechanical movement and force.

The solenoids that make up so much of our world are actually rather simple devices that just need a rudimentary understanding of the physics that most of us acquired in middle school. You don’t need to know any mathematical formulas to understand them, and doing so is not difficult.

What is solenoid ?

Electromagnets

Electromagnets are magnets with an iron core and a wire encircling it. The iron core generates a magnetic field all around it when an electric current flows through it. The magnetic field vanishes when the electricity is turned off. Magnets have ferromagnetic or ferrimagnetic cores that are surrounded by wires. Iron is the most frequently used material in the core.

The magnetic field that is produced depends on the amount of power available. Because the magnetic field cannot be changed, a permanent magnet does not require an electrical source. Magnets are used to create a variety of devices, including hard drives, relays, motors, loudspeakers, generators, MRI machines, solenoids, and more.

Let’s study about solenoids now that we’ve gained a better understanding of electromagnets.

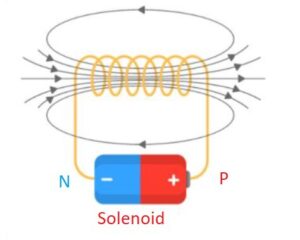

Its function is to produce a regulated magnetic field through a coil twisted into a compact helix. The solenoid is a sort of electromagnet. As seen in the following diagram, the solenoid The plunger is constructed of soft iron, and the solenoid is a coil of wire. When an electric current flows through a coil, a magnetic field is created around the coil, which pulls the plunger in. We can infer that electrical energy is transformed into mechanical work by the solenoid.

The creation of more powerful and effective magnets led to the creation of solenoids. Andre-Marie Ampere, a French physicist and mathematician, first used the term “solenoid” to describe a helical coil in 1823.

How Solenoid Work

Let’s discover how solenoids function after knowing what a solenoid is and what its components are. Electromagnetism is the basis for solenoid operation. The magnetic field is produced when the coil is subjected to an electric current. When a metal core is inserted inside the coil, the magnetic lines of flux are concentrated on the metal core. As contrasted with the air core, this increases the coil’s induction. “Electromagnetic induction” is the name for this idea.

As we all know, coils are constructed from copper wire that has been tightly wound with multiple turns. As the current flows across the wire, a powerful magnetic flux is created. High flux concentrations are found on the core, although some flux also manifests at the coil’s ends and outside the coil. The magnetic strength of the solenoid may be raised by increasing either the electric current flow or the number of turns.

Steel or iron make up the housing. The magnetic field produced by the coil surrounds the housing. Through the plunger, mechanical force is put to use. Solenoids also have positive and negative poles, which may attract or repel objects.

Think about a solenoid whose length exceeds its radius. A wire helix is used to wrap enameled and insulated wire, leaving a little space between each turn. Both the total magnetic field made by the solenoid and the amount of vector force made by each turn are equal to the size of a circle. This displays the solenoid’s whole magnetic field. The lines of magnetic fields made inside a finite solenoid are shown in the diagram below.

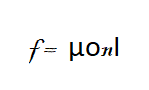

Anywhere past the solenoid, the field is quite narrow. The solenoid’s internal field is always parallel to its axis. The Law of the Ampere may be used to describe the magnetic force that a solenoid produces:

Where I is the current flowing through the wire, n is the number of twists the wire has per unit length, and the right-hand thumb rule is used to evaluate the direction.

Different Solenoid Types

The following list includes many solenoid types:

- AC-Laminated Solenoid

- DC-C Frame Solenoid

- DC-D Frame Solenoid

- Linear Solenoid

- Rotational Solenoid

Tell us about each solenoid type.

Solenoid with AC-Lamination

It is generally known how much force may be applied during the initial stroke of an AC-laminated solenoid. The metal core and wire coil of the AC-laminated solenoid are present. To lessen stray current, the solenoid’s core is built of laminated metal. More strokes may be used by AC-laminated solenoids than DC-laminated solenoids. When operating, this kind of solenoid emits a clear buzzing sound.

DC C-Frame Solenoid

One C-shaped frame surrounds the coil on the DC power C-frame solenoid. Based on what it says about itself, the DC power C-frame solenoid has a DC design and can be used with machines that can work with AC power.

DC-D Frame Solenoid

The coil is protected by a two-piece frame on a DC-D frame solenoid. It may also be used with AC power and features a regulated stroke operation.

Linear Solenoid

A coil of wire is wrapped around a movable metal core in a linear solenoid. It helps while pushing or tugging on a mechanical device. Devices for beginners employ linear solenoids. This technique helps close a circuit and let electricity flow.

Rotational Solenoid

The automated control technique uses a rotary solenoid. This solenoid likewise contains a core and a coil, but it functions differently.

What is a solenoid value?

Similar to other valves, solenoid valves control the flow of gases and liquids. They have a solenoid that enables such valves to operate electrically to open or close.

These valves can be produced in either a commonly open or commonly closed configuration.

A solenoid valve is in the off position when the moveable core is resting on the valve base and there is no current flowing through the wires. As a result, the valve is sealed since the gas or liquid behind it cannot pass through.

The magnetic field is produced by passing electricity through the wire coil; this field causes the core to rise, allowing the liquid or gas to easily travel through the valve. When the electricity is turned off, the core returns to its initial position, shutting the valve and stopping the flow of gas or liquid. A usually closed valve serves this purpose by remaining closed until it is opened by electricity.

The same rules apply, but a solenoid valve that is usually open is meant to work in the opposite direction. The core stays in the up position with the valve open when it is in the off position, enabling media to pass through. When the valve is turned on, the core is forced to descend, stopping the flow and closing the valve.

A solenoid capacity

You have used a little solenoid if you have ever used a pneumatic tool. You had compressed air in your compressor. You pulled the trigger on your nail gun to cause a puff of that compressed air to drive a nail for you. As soon as you did that, a solenoid valve briefly opened, allowing a burst of pressurized air to be released from the compressor into the cannon to drive that nail.

A solenoid in a bigger device, which might be in charge of more liquid or gas, needs more power than a small valve like that one. How much power is available from a solenoid depends on how many coils are in the wire and how much current is passed through them.

You can determine the number of coils and the amount of current a solenoid valve needs to operate using the magnetic field equation, which is based on Ampere’s law and uses these elements to determine how strong the electromagnetic field is.

Applications

Depending on the situation, stronger or weaker solenoids are used. Your doorbell might ring even if it doesn’t have a big, strong solenoid, a lot of coils, or a lot of electricity. To do this, a tiny solenoid can be used.

However, an oil derrick would require a far more potent solenoid valve. Since an electromagnet can’t work without electricity, all solenoids need it, but different kinds are needed for the different jobs they do.

Electrical. Since electricity should be involved, this word applies to all solenoid valves.

Pneumatic. These solenoid valves enable the suppression and flow of gases like carbon dioxide, nitrogen, and air.

Hydraulic. a valve that controls the flow of liquids, such as gasoline, alcohol, and water.

.

Solenoids and solenoid valves are all around us in modern life when you start looking for them, and they greatly simplify many of the tasks we do on a daily basis.

Your car’s solenoid may one day fail to start or your solenoid valve may stop opening and closing. There are a few straightforward approaches to diagnosing these issues, which is essential for solving them.

Utilizing a compass is the easiest method. Since your solenoid relies on electromagnetism to operate, if the solenoid isn’t working, there won’t be a magnetic field around it.

If you put a compass near the solenoid and then turn it on, you can quickly tell if the solenoid is the problem or if there is another mechanical problem. The solenoid generated a magnetic field, which caused your compass needle to leap. If not, the required voltage is not reaching your solenoid.

With a multimeter, you may further pinpoint the problem in this situation. Checking the connections is the first thing you should do, though, before that. Even if the solenoid is in perfect condition, it won’t operate if your positive (+) or negative (-) terminals are broken, disconnected, or otherwise defective. Even if the connections appear to be secure, you should still check the solenoid’s continuity using your multimeter.

Switch your multimeter to the resistance setting once you’ve confirmed that the connections are sound. A measurement of more than 0.3 ohms indicates that the device isn’t operating properly. It must be replaced since it cannot conduct electricity well enough to function.

For more information on how to identify and address issues with solenoid valves, visit our troubleshooting page.

Conclusion

Solenoid valves and solenoids are incredibly common in today’s world. They convert electrical signals into sound, which we use to control dishwashers, start cars, operate dialysis machines, and even command speakers to play music. Even though solenoid devices are simple inventions, our lives would be very different without them.

Solenoids can be made in a high school science class with some wire, a magnetic core, and electricity. They are important to many different processes, and some of them wouldn’t work at all without them.

Leave a Reply