1- Introduction to Amorphous Transformers

Amorphous transformers are an example of technical innovation and efficiency in the field of electrical engineering. With notable improvements over conventional transformer types, these transformers mark a substantial leap forward in transformer functioning and design.

“Amorphous” describes the special structure of the material that makes up the transformer’s core. Amorphous transformers use non-crystalline alloys, which are distinguished by their disordered atomic structure, as opposed to conventional transformers, which use crystalline alloys.

Amorphous transformers are able to attain better levels of performance and energy efficiency because of their unique material composition. Amorphous transformers can function at much lower energy consumption levels by eliminating energy losses related to core magnetization and demagnetization cycles.

Applications for amorphous transformers may be found in many different fields and industries, including home electrical systems and power distribution networks. They are the go-to option for contemporary electrical infrastructure projects because of their capacity to increase energy efficiency and lessen environmental effect.

2-What Makes a Transformer Amorphous?

In the context of transformers, the term “amorphous” describes the special material composition of the transformer’s core. Amorphous transformers use non-crystalline alloys instead of crystalline ones, such silicon steel, as do regular transformers.

The disorganized atomic structure of a transformer’s core material is the primary attribute that causes it to become amorphous. The transformer core is manufactured with a quick cooling procedure to create this non-crystalline structure.

Iron, boron, and silicon are commonly found in amorphous transformer core compositions. The molten alloy is quickly cooled throughout the manufacturing process, which prevents the creation of crystalline structures and leaves the atomic arrangement amorphous, or non-crystalline.

Comparing this amorphous structure to conventional crystalline cores reveals various benefits. By lowering core losses brought on by cycles of magnetization and demagnetization, it raises energy efficiency and lowers operating temperatures.

Moreover, the non-crystalline structure of the core material reduces the possibility of eddy current production, which in traditional transformers causes extra energy losses. Because of this, amorphous transformers may function with more efficiency and help save energy overall.

3- Definition and Characteristics

The phrase “amorphous transformers” describes a particular kind of transformer that has a non-crystalline metal core. Amorphous transformers have non-crystalline alloy cores as opposed to standard transformers, which are made of crystalline alloys like silicon steel.

The main feature of amorphous transformers is their distinct atomic structure, which is different from crystalline materials’ ordered organization. Amorphous alloys, on the other hand, are amorphous because of the randomly scattered atoms that make up the substance.

By quickly cooling the alloy during the production process, crystalline grains cannot form in the alloy, giving it this non-crystalline structure. As a result, the atoms are unable to arrange themselves into a regular lattice structure, which gives amorphous materials their typical disorderly layout.

An important factor in the remarkable performance qualities of amorphous transformer cores is their non-crystalline structure. In comparison to conventional transformers, it contributes to the reduction of core losses brought on by variations in magnetic flux, resulting in increased energy efficiency.

Amorphous transformers also show reduced eddy current losses and magnetic hysteresis, which increases their efficiency and lowers their energy usage. Because of this, they are a desirable choice for applications that prioritize environmental sustainability and energy efficiency.

4-Material Composition

Amorphous transformers’ material composition plays a crucial role in both their functionality and design. Amorphous transformers make use of certain non-crystalline alloys as opposed to conventional transformers, which frequently employ crystalline alloys like silicon steel.

Usually, amorphous transformers are made of a mixture of silicon, boron, and iron as their core material. These components have been carefully chosen and put together to produce the precise magnetic and electrical characteristics needed for effective transformer operation.

The alloy combination is heated to a molten state during the production process and quickly chilled to generate the non-crystalline structure that characterizes amorphous materials. An uneven atomic arrangement results from the atoms’ inability to organize themselves into a normal crystalline lattice due to the quick cooling.

The core material’s non-crystalline structure is crucial for reducing energy losses in the transformer. It lowers magnetic hysteresis and eddy current losses, two main causes of inefficiency in conventional transformers with crystalline cores.

Amorphous transformers may operate at lower temperatures and reach better levels of performance and energy efficiency by employing non-crystalline alloys. Because of this, they are especially well-suited for applications that prioritize environmental sustainability and energy efficiency.

5- How Do Amorphous Transformers Work?

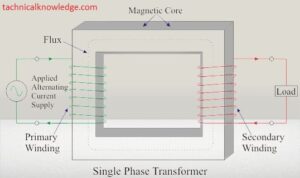

5.1 Magnetic Core Structure

The magnetic core structure is a fundamental component of amorphous transformers, playing a crucial role in their operation and efficiency. Unlike traditional transformers with cores made of crystalline alloys, the cores of amorphous transformers are constructed using specialized non-crystalline alloys.

Amorphous transformers’ core construction aims to reduce energy losses brought on by variations in magnetic flux when the device is in use. This is made possible by the core material’s special atomic arrangement, which is non-crystalline or amorphous in nature.

Eddy currents and magnetic hysteresis are two examples of core losses that can be decreased by more effective magnetization and demagnetization procedures made possible by the non-crystalline structure of the core material. Because of this, amorphous transformers are able to function more efficiently than their conventional equivalents.

Usually, the amorphous alloy’s thin strips are wound into a toroidal shape to produce the core structure, which is a closed magnetic circuit. This transformer’s design maximizes energy transmission between its main and secondary windings while minimizing magnetic flux leakage.

Furthermore, amorphous transformers’ core structures are meticulously designed to guarantee that the core material’s magnetic characteristics are constant. This aids in maximizing the transformer’s efficiency and reducing losses under a variety of operating circumstances.

5.2 Energy Efficiency Mechanism

One of the main characteristics that distinguishes amorphous transformers from conventional transformers and adds to their improved performance in electrical applications is their energy efficiency mechanism.

An amorphous transformer’s distinct magnetic core structure is what powers its energy efficiency mechanism. Amorphous transformers use cores consisting of certain non-crystalline alloys, in contrast to conventional transformers that use cores made of crystalline alloys.

Amorphous transformers can reduce energy losses related to magnetization and demagnetization processes because of the non-crystalline nature of the core material. This is accomplished via a number of mechanisms:

- Reduced Eddy Current Losses: Eddy currents are induced currents that circulate within the core material and contribute to energy losses through resistive heating. The non-crystalline structure of the core material in amorphous transformers effectively suppresses the formation of eddy currents, leading to reduced energy losses.

- Lower Magnetic Hysteresis Losses: Magnetic hysteresis refers to the phenomenon where a material retains a certain amount of magnetization even after the magnetic field is removed. Amorphous alloys exhibit lower magnetic hysteresis compared to crystalline alloys, resulting in reduced energy losses during magnetization and demagnetization cycles.

- Enhanced Magnetic Properties: The unique composition of the non-crystalline alloy used in amorphous transformers allows for improved magnetic properties, such as higher magnetic permeability and lower coercivity. These properties enable more efficient magnetic flux transfer and minimize energy losses within the transformer core.

As a result of these energy efficiency mechanisms, amorphous transformers can operate at higher levels of efficiency compared to traditional transformers. They consume less energy during operation, leading to reduced electricity costs and lower environmental impact.

6- Advantages of Amorphous Transformers

Amorphous transformers offer several advantages over traditional transformers, making them a preferred choice for various electrical applications:

- Energy Savings: One of the most significant advantages of amorphous transformers is their high energy efficiency. The unique magnetic core structure and material composition of amorphous transformers result in reduced energy losses during operation. This translates into lower electricity consumption and significant cost savings over the lifespan of the transformer.

- Environmental Impact: Due to their superior energy efficiency, amorphous transformers contribute to environmental conservation efforts. By consuming less energy and reducing greenhouse gas emissions associated with electricity generation, amorphous transformers help mitigate environmental impact and promote sustainable energy practices.

- Reduced Heat Generation: Amorphous transformers operate at lower temperatures compared to traditional transformers. The reduced heat generation not only improves the lifespan of the transformer but also enhances safety by minimizing the risk of overheating and electrical failures.

- Enhanced Performance: Amorphous transformers exhibit improved performance characteristics, including higher efficiency and better voltage regulation. This ensures stable and reliable power distribution, especially in applications where consistent voltage levels are critical.

- Longer Lifespan: The advanced design and materials used in amorphous transformers contribute to their durability and longevity. With proper maintenance and care, amorphous transformers can operate efficiently for decades, providing reliable power distribution without the need for frequent replacements.

- Noise Reduction: Amorphous transformers generate less noise during operation compared to traditional transformers. This is attributed to the smoother magnetic flux transitions and reduced vibration within the transformer core, resulting in quieter operation and improved working conditions in sensitive environments.

- Compliance with Energy Standards: Many countries and regions have established energy efficiency standards and regulations for electrical equipment, including transformers. Amorphous transformers typically meet or exceed these standards, ensuring compliance with regulatory requirements and facilitating access to government incentives and rebates.

7- Applications of Amorphous Transformers

Amorphous transformers find diverse applications across various sectors due to their superior energy efficiency, environmental sustainability, and performance characteristics. Some of the key applications include:

- Industrial Sector: Amorphous transformers are widely used in industrial settings for a range of applications, including power distribution, motor control, and equipment operation. Industries such as manufacturing, mining, and construction rely on amorphous transformers to efficiently manage electrical power and maintain stable operations.

- Commercial Buildings: In commercial buildings, such as office complexes, shopping malls, and hotels, amorphous transformers play a crucial role in providing reliable and energy-efficient power distribution. They help regulate voltage levels, reduce energy consumption, and minimize operational costs, contributing to sustainable building practices and environmental conservation efforts.

- Residential Sector: Amorphous transformers are increasingly being integrated into residential electrical systems to enhance energy efficiency and reduce electricity bills. They power household appliances, lighting systems, and HVAC (heating, ventilation, and air conditioning) units, enabling homeowners to minimize their carbon footprint and lower utility expenses.

- Renewable Energy Systems: With the growing adoption of renewable energy sources such as solar and wind power, amorphous transformers play a vital role in facilitating the integration of renewable energy systems into the electrical grid. They help manage fluctuations in power output, improve grid stability, and optimize energy transfer, supporting the transition to a sustainable and decentralized energy infrastructure.

- Transportation Infrastructure: Amorphous transformers are utilized in transportation infrastructure, including railway networks, subway systems, and electric vehicle charging stations. They provide efficient power distribution and voltage regulation for critical transportation operations, ensuring reliable service and minimizing downtime.

- Data Centers: In data centers and IT facilities, where uninterrupted power supply is essential for maintaining operations, amorphous transformers help ensure reliable and energy-efficient power distribution. They support the high-demand power requirements of servers, networking equipment, and cooling systems, while minimizing energy losses and environmental impact.

- Utilities and Power Grids: Amorphous transformers play a key role in utility-scale power distribution and transmission networks. They help reduce transmission losses, improve voltage regulation, and enhance grid resilience, enabling utilities to deliver electricity more efficiently and reliably to end-users.

8- Comparison with Traditional Transformers

8.1 Amorphous Transformers:

- Core Material: Amorphous transformers use non-crystalline alloys such as iron, boron, and silicon for their core material.

- Energy Efficiency: Amorphous transformers exhibit higher energy efficiency due to reduced core losses, including eddy current and hysteresis losses.

- Environmental Impact: Amorphous transformers contribute to environmental conservation by consuming less energy and reducing greenhouse gas emissions.

- Cost: Initially, amorphous transformers may have a higher upfront cost compared to traditional transformers due to the specialized manufacturing process and materials.

- Performance: Amorphous transformers offer improved performance characteristics, including better voltage regulation and lower operating temperatures.

- Longevity: Amorphous transformers have a longer lifespan compared to traditional transformers, resulting in reduced maintenance and replacement costs over time.

8.2 Traditional Transformers:

- Core Material: Traditional transformers typically use crystalline alloys like silicon steel for their core material.

- Energy Efficiency: Traditional transformers have higher core losses compared to amorphous transformers, resulting in lower energy efficiency.

- Environmental Impact: Traditional transformers contribute to energy waste and environmental pollution due to higher energy consumption and greenhouse gas emissions.

- Cost: Traditional transformers may have a lower initial cost compared to amorphous transformers, but they incur higher operating expenses over their lifespan.

- Performance: Traditional transformers may exhibit lower performance levels, including less efficient voltage regulation and higher operating temperatures.

- Longevity: Traditional transformers may have a shorter lifespan compared to amorphous transformers, leading to higher maintenance and replacement costs.

9- Conclusion

In summary, compared to conventional transformers, amorphous transformers provide improved efficiency, lower energy consumption, and environmental sustainability, marking a substantial achievement in electrical engineering. Amorphous transformers minimize energy losses by using non-crystalline alloys for their cores, which lowers operating costs and greenhouse gas emissions. The long-term advantages of amorphous transformers, including energy savings and a prolonged lifespan, make them a popular option for a variety of applications across industries and sectors, despite their initial higher cost. Amorphous transformers are essential for stimulating innovation and influencing the development of a more sustainable future for electrical infrastructure globally, particularly as the need for energy-efficient solutions keeps rising.

10- Unique FAQs

What is the amorphous transformer?

An amorphous transformer is a type of electrical transformer with a core made of non-crystalline alloys. Unlike traditional transformers with crystalline cores, amorphous transformers offer higher energy efficiency and reduced energy losses. They are known for their superior performance and are used in various industries where energy conservation is important.

What is a amorphous core?

An amorphous core is a type of transformer core made from non-crystalline alloys. Unlike traditional cores, which are crystalline, amorphous cores offer higher energy efficiency and lower energy losses. They are used in transformers for improved performance and reduced environmental impact.

What are 3 types of amorphous?

1. Iron-based amorphous alloys: These alloys typically contain iron as the primary element along with small amounts of other elements such as boron and silicon. They are widely used in transformer cores due to their excellent magnetic properties and high energy efficiency.

2. Cobalt-based amorphous alloys: These alloys contain cobalt as the primary element and are known for their high magnetic saturation levels and corrosion resistance. They are used in various applications, including magnetic recording media and sensors.

3. Nickel-based amorphous alloys: These alloys contain nickel as the primary element and are known for their high magnetic permeability and low coercivity. They are used in applications requiring high sensitivity to magnetic fields, such as magnetic sensors and magnetic shielding.

Leave a Reply