Table of Contents

Dry type transformer: An In-Depth Guide

Transformers play an integral role in the electricity supply chain. They help in converting electrical energy from one voltage level to another, making it easier for transmission and distribution. Dry type transformers are a popular type of transformer that have become more and more common in recent years. In this article, we will tell you everything you need to know about dry-type transformers, including what they are, how they work, what their advantages are, and what they can be used for.

1-What is a dry type transformer

A dry type transformer is a type of transformer that uses air as a cooling medium instead of oil. It is also known as a “cast resin” transformer because the HV and LV windings are both cast in epoxy resin, which provides excellent electrical insulation properties and mechanical strength. Unlike oil-filled transformers, dry type transformers do not pose a fire hazard or release toxic substances in the event of a fault, making them safer and more environmentally friendly.

Dry type transformers are used for a wide range of tasks, such as making, distributing, and sending electricity. They are also used in industrial, commercial, and residential settings. They are available in a range of sizes and voltage ratings, from small low-voltage transformers used in electronic devices to large high-voltage transformers used in power grids.

One of the key advantages of dry type transformers is their reliability and low maintenance requirements. Since they do not require oil to cool the windings, there is no risk of oil leaks or contamination, and the transformer can operate in a wide range of temperatures and environments. They are also quieter and last longer than oil-filled transformers, which means they cost less overall.

Despite their advantages, dry type transformers are typically more expensive than oil-filled transformers, especially for high voltage and high power applications. Additionally, their cooling capabilities may be limited compared to oil-filled transformers, which may require additional cooling systems to be installed.

Overall, dry type transformers offer a safe, reliable, and environmentally friendly option for power generation, distribution, and transmission and are a popular choice in many industries and applications.

2-Types of Dry type transformers

Dry type transformers are classified into two types based on their insulation systems: VPI (Vacuum Pressure Impregnated) and Cast Resin. Under vacuum pressure, epoxy resin is sucked into the windings of a VPI transformer, while cast resin transformers are made by pouring epoxy resin into a mold that already has the windings in it. Cast-resin transformers are more commonly used due to their high insulation and short-circuit strength. More dry-type transformer types are used in manufacturing around the world.

2- (a) Self-cooled dry-type transformer:

A self-cooled dry-type transformer is a type of transformer that uses natural air convection to cool the transformer coils. Most of the time, the coils of a transformer are enclosed in a sealed case made of non-flammable material, like steel or aluminum. The enclosure is vented to allow for air circulation, which helps dissipate heat generated by the transformer.

A self-cooled dry-type transformer is made to be installed indoors in a well-ventilated area. It is often used in places where noise is a problem, such as hospitals, schools, and office buildings. This type of dry-type transformer is usually smaller and easier to install than other types because it doesn’t need any extra cooling equipment.

One problem with a self-cooled dry-type transformer is that it might not work well in situations where the temperature around it is high because the transformer might not be able to get rid of heat well enough. In such cases, a forced-air-cooled or cast-resin dry-type transformer may be more appropriate.

Talking to a qualified electrical engineer is the best way to figure out which type of transformer is best for a certain application, taking into account things like voltage and power needs, load characteristics, environmental factors, and safety.

2-(b) Forced-air-cooled dry-type transformer:

A forced-air-cooled dry-type transformer is a type of transformer that uses fans to force air over the transformer coils to improve cooling. The fans can be internal or external to the transformer enclosure, and they may be mounted on the top or sides of the enclosure.

The fans create a flow of air that helps dissipate heat generated by the transformer coils. This makes it possible for the transformer to work at a higher power density than a self-cooled dry-type transformer, which makes it good for applications that need a lot of power. The increased cooling capacity also makes it possible to use the transformer in environments with higher ambient temperatures.

A forced-air-cooled dry-type transformer is commonly used in a wide range of applications, including power distribution, lighting, and motor control. This type of transformer is typically designed for indoor use in a well-ventilated area, and it may be installed as a standalone unit or as part of a larger electrical system.

A forced-air-cooled dry-type transformer may be harder to install and maintain than a self-cooled dry-type transformer. The fans require additional power, and they may be subject to failure or damage over time. But regular maintenance and inspections can help make sure the transformer works well for its entire life.

Talking to a qualified electrical engineer is the best way to figure out which type of transformer is best for a certain application, taking into account things like voltage and power needs, load characteristics, environmental factors, and safety.

2- (c) Cast-resin dry-type transformer:

A cast-resin dry-type transformer is a type of transformer that uses epoxy resin to encapsulate the transformer coils. The resin acts as an insulator and provides a high level of protection against environmental factors such as moisture, dust, and other contaminants.

This type of transformer is designed for indoor or outdoor use, and it is typically more resistant to damage from humidity, chemicals, and other environmental factors than other types of dry-type transformers. Cast-resin transformers are also highly resistant to fire, making them a popular choice for applications where fire safety is a concern.

Putting epoxy resin around the transformer coils gives them a high level of mechanical stability and makes them less likely to be damaged by vibration, shock, and other outside forces. Cast-resin dry-type transformers are often used for power distribution, renewable energy, and industrial control, among other things.

One potential disadvantage of a cast-resin dry-type transformer is that it may be more expensive than other types of dry-type transformers. The process of encapsulation is complicated and needs special tools. Using epoxy resin can also raise the cost of making something. But cast-resin transformers may be a good choice in the long run, especially in harsh environments, because they last longer and are less likely to catch fire.

Talking to a qualified electrical engineer is the best way to figure out which type of transformer is best for a certain application, taking into account things like voltage and power needs, load characteristics, environmental factors, and safety.

2- (d) Open-wound dry-type transformer:

An open-wound dry-type transformer is a type of transformer that has its windings exposed to the environment without any form of enclosure or encapsulation. This makes it one of the simplest and most economical forms of a dry-type transformer.

In an open-wound transformer, the coils are typically made of copper or aluminum and are wound around a core made of laminated steel. The transformer could also have cooling fins or some other kind of cooling mechanism to get rid of the heat it makes while it’s working.

While open-wound, dry-type transformers are simple and cost-effective, they are also more vulnerable to environmental factors such as moisture, dust, and other contaminants. This can lead to the degradation of the insulation over time, reducing the performance and lifespan of the transformer. Open-wound transformers are also more susceptible to damage from mechanical factors such as vibration, shock, or impact.

Despite these limitations, open-wound transformers can be suitable for certain applications where cost is a primary concern and the environment is relatively stable and free from contaminants. However, it is important to consult with a qualified electrical engineer to determine whether an open-wound transformer is appropriate for a specific application, nd to ensure that all safety and regulatory requirements are met.

2- (E) Encapsulated Dry-Type Transformer:

A type of transformer called an “encapsulated dry-type transformer” is sealed in a container that is usually made of a strong resin. The encapsulation gives the transformer a high level of environmental protection by keeping out moisture, dust, and other harmful things.

Encapsulated dry-type transformers can be designed for indoor or outdoor use and are commonly used in harsh environments or where exposure to the elements is a concern. The encapsulation also gives a high level of mechanical protection, making it less likely that vibration, shock, or impact will damage the device.

Encapsulated transformers are typically designed to be maintenance-free, with no need for additional insulation or cooling systems. They can be equipped with additional features such as temperature sensors or alarms to provide additional protection against overloading or overheating.

One potential disadvantage of encapsulated dry-type transformers is that they can be more expensive than other types of dry-type transformers due to the cost of the encapsulation process. Additionally, encapsulation may affect the heat dissipation of the transformer, which can limit its power output or require additional cooling mechanisms.

As with any type of transformer, it’s important to talk to a qualified electrical engineer to figure out which type will work best for a particular application, taking into account things like voltage and power needs, load characteristics, environmental factors, and safety concerns.

2- (F) Low-voltage dry type transformer:

A low-voltage dry type transformer is a type of transformer that is designed to convert low voltage electrical energy to a higher voltage. The term “low voltage” generally refers to electrical systems operating at voltages of 600 volts or less.

When low-voltage energy needs to be increased to a higher voltage for transmission or distribution, low-voltage dry-type transformers are frequently used in a range of industrial, commercial, and residential applications. They are suitable for applications where the transformer won’t be exposed to moisture, dust, or other environmental contaminants because they are typically designed for use in indoor environments.

Copper, aluminum, and laminated steel cores are just a few of the materials that can be used to build low-voltage dry-type transformers. They can also have a variety of cooling components, like fans or heat sinks, to remove the heat produced during operation.

Low-voltage dry type transformers have the benefit of generally being safer than conventional oil-filled transformers because they don’t contain any potentially dangerous fluids. Additionally, they are frequently smaller and lighter in weight, which makes them simpler to install and transport.

As with any type of transformer, it is crucial to seek the advice of a licensed electrical engineer to choose the right model and specifications for a given application while taking into account variables like voltage and power requirements, load characteristics, environmental considerations, and safety concerns.

2- (g) Medium-voltage dry-type transformer:

A medium-voltage dry type transformer is a type of transformer that is designed to convert medium voltage electrical energy to a higher or lower voltage. Electrical systems that operate at voltages between 1 kV and 72.5 kV are generally referred to as “medium voltage” systems.

When medium voltage energy needs to be stepped up or down for transmission or distribution, a variety of industrial, commercial, and utility applications use medium-voltage dry-type transformers. They can be used in harsh environments where the transformer may be exposed to moisture, dust, or other environmental contaminants because they are typically designed for use in indoor or outdoor environments.

A variety of materials, such as laminated steel cores and copper or aluminum windings, can be used to build medium-voltage dry-type transformers. In order to dissipate the heat produced during operation, they can also be fitted with a variety of cooling components, such as fans or heat sinks.

Due to the fact that they don’t contain any potentially hazardous fluids, medium-voltage dry-type transformers have the advantage of being generally safer than traditional oil-filled transformers. They are also typically smaller and lighter than their oil-filled counterparts, which makes them simpler to transport and install.

As with any type of transformer, it’s important to talk to a qualified electrical engineer to figure out the right type and specs for a particular application. This means taking into account things like voltage and power needs, load characteristics, environmental factors, and safety concerns.

2- (h) High-voltage dry-type transformer:

A high-voltage dry-type transformer is a type of transformer that is designed to convert high voltage electrical energy to a higher or lower voltage. The term “high voltage” generally refers to electrical systems operating at voltages above 72.5 kV.

High-voltage dry-type transformers are used in a variety of industrial, commercial, and utility applications where high voltage energy needs to be stepped up or down for transmission or distribution. They can be used in harsh environments where the transformer may be exposed to moisture, dust, or other environmental contaminants because they are typically designed for use in indoor or outdoor environments.

Copper or aluminum windings and laminated steel cores are just a couple of the materials that can be used to build high-voltage dry-type transformers. They can also have a variety of cooling components, like fans or heat sinks, to remove the heat produced during operation.

One advantage of high-voltage dry-type transformers is that they are generally safer than traditional oil-filled transformers, as they do not contain any hazardous fluids. They are also typically more compact and lighter in weight than their oil-filled counterparts, making them easier to install and transport.

As with any type of transformer, it’s important to talk to a qualified electrical engineer to figure out the right type and specs for a particular application. This means taking into account things like voltage and power needs, load characteristics, environmental factors, and safety concerns.

2- (i) Class F dry-type transformer:

A Class F dry-type transformer is a type of transformer that is designed with electrical insulation materials rated for use in high-temperature applications. The “F” in “Class F” stands for “155 degrees Celsius,” which is the maximum allowable temperature rise for the transformer’s windings under full load conditions.

The insulation materials used in Class F transformers are typically made from varnish or epoxy resin, which has good electrical and mechanical properties and can withstand high temperatures without degrading. This means that Class F transformers can be used in places where the temperature is high, like steel mills or chemical plants.

Class F dry-type transformers are available in a wide range of sizes and configurations and can be designed for a variety of voltages and power levels. They usually cost more than transformers with lower insulation classes, but because they can handle high temperatures, they can be used in tough situations.

Even though Class F insulation materials can handle high temperatures, the transformer as a whole should still be made to work at a safe temperature to make sure it works well for a long time. It is also important to talk to a qualified electrical engineer to figure out the right insulation class for a certain application, taking into account things like voltage and power needs, the environment, and safety.

2-(j) Class H dry-type transformer:

The type of dry-type transformer selected for a specific application depends on a variety of factors, including the voltage and power requirements, environmental factors, and load characteristics.

3- Construction of a Dry Type Transformer

A dry type transformer is made up of a core, a primary winding, a secondary winding, and an insulation system. The core is made up of high-quality electrical steel laminations that are stacked and joined together. The windings are then placed around the core and are separated by the insulation system, which is made up of various types of insulation materials. The whole assembly is then put into a protective case that protects it from the outside world.

4- What is used insulation class in dry type transformer

The temperature rating of the insulation used in a dry type transformer is what is meant by the term “insulation class.” The insulation system is an important part of the transformer because it keeps the windings and the core from touching each other electrically and keeps the electricity from breaking down because of high voltages.

The temperature rating of the insulation used in the transformer is used to figure out the insulation class. Different types of insulation have different temperature ratings. These ratings are based on the highest temperature that the material can handle without breaking down or losing its ability to insulate.

In dry-type transformers, the most common insulation classes are Class F, Class H, and Class H-180. Class F insulation has a temperature rating of 155°C, while Class H insulation has a temperature rating of 180°C. Class H-180 insulation can handle temperatures up to 180 °C, but it also has to pass an extra test to make sure it can handle high temperatures for a long time.

When choosing the insulation class for a dry-type transformer, it’s important to think about both the transformer’s operating temperature and the rise in temperature of the windings when the transformer is under load. The insulation class must be chosen so that the transformer can work safely and reliably without the insulation deteriorating or breaking down.

It is also worth noting that the insulation class of a dry-type transformer can have an impact on the transformer’s efficiency. Insulation materials that can handle higher temperatures may be more efficient because they let the transformer work at higher temperatures without breaking down. But it’s important to find a good balance between efficiency, safety, and reliability and to choose the right insulation class based on what the transformer needs.

5- What is difference between insulation class F and H

The main difference between insulation classes F and H is their temperature rating. Class F insulation has a temperature rating of 155°C, while Class H insulation has a temperature rating of 180°C.

This means that Class H insulation can keep its insulating properties at higher temperatures than Class F insulation. So, dry-type transformers with Class H insulation can work at higher temperatures and may be more efficient than those with Class F insulation.

However, it’s important to note that a transformer’s insulation class is just one factor that determines its overall temperature rating. Other factors, such as the design of the transformer and the ambient temperature of the operating environment, also play a role in determining the maximum temperature that the transformer can safely withstand.

When selecting a transformer, it’s important to consider the specific requirements of the application and select an insulation class that can safely and reliably meet those requirements. In general, Class H insulation is recommended for applications that require higher operating temperatures or have more demanding temperature requirements than Class F insulation can provide.

6- Working Principle of a Dry Type Transformer

Dry-type transformers work on the principle of electromagnetic induction. When a current that changes direction flows through the primary winding, it creates a magnetic field in the core that also changes direction. This magnetic field induces a voltage in the secondary winding, which is then transmitted to the load. The efficiency of a transformer is measured by its ability to transmit power with minimal loss.

7- How much %impedance is better for dry type transformer

The percentage impedance of a dry-type transformer depends on a number of factors, including the specific application and the load that the transformer will be powering. In general,

A transformer with a higher percentage impedance will have a lower short-circuit current and may provide better protection for the load in case of a fault.

The percentage impedance is a way to measure the internal resistance of a transformer. It is given as a percentage of the transformer’s rated voltage. A typical range for the percentage impedance of a dry-type transformer is between 3% and 6%.

A transformer with a lower percentage of impedance will have a higher short-circuit current and may be better for applications where the load needs a high starting current or where the system fault level is high. But a transformer with a higher percentage of impedance will have a lower short-circuit current and may be better for applications where the load is sensitive to voltage drops or where the system fault level is low.

It’s important to remember that the percentage impedance of a dry-type transformer should be chosen based on the specific needs of the application, such as the characteristics of the load and the expected fault level. If the percentage of impedance on a transformer is too high or too low, it may not work well or may not protect the load well enough.

In general, a percentage impedance of between 3% and 5% is commonly used for dry-type transformers. But the exact percentage of impedance needed for a given application should be figured out by doing a thorough analysis of the system’s needs and the transformer’s performance.

8- Which better Cooling Mechanism AN or AN/AF

The choice of cooling mechanism for a dry-type transformer depends on a number of factors, including the transformer’s power rating, ambient temperature, and operating conditions. The two most common cooling mechanisms for dry-type transformers are natural air cooling and forced air cooling.

Natural air cooling, also known as AN or AN/AF, uses natural convection to cool the transformer. This type of cooling is suitable for low-power transformers with a rating of up to a few hundred kilovolt-amperes (kVA). Natural air cooling is relatively simple and does not require any additional equipment or power supply.

Forced air cooling, also known as AF or AFAF, uses fans to force air over the transformer’s coils to enhance heat dissipation. This type of cooling is suitable for higher-power transformers with a rating of several hundred kVA up to several megavolt-amperes (MVA). Forced air cooling is more efficient than natural air cooling and can help increase the transformer’s power output and overall efficiency.

The choice between natural air cooling and forced air cooling depends on the specific requirements of the application, including the transformer’s power rating, ambient temperature, and operating conditions. In general, forced air cooling is more efficient than natural air cooling and is preferred for high-power transformers or applications with high ambient temperatures.

However, forced air cooling can also be more complex and expensive to install and maintain, as it requires additional equipment and a power supply. Natural air cooling, on the other hand, is simpler and more cost-effective but may not provide sufficient cooling for high-power transformers or applications with high ambient temperatures.

Ultimately, the choice of cooling mechanism for a dry-type transformer should be based on a detailed analysis of the application’s requirements and the transformer’s performance characteristics in order to select the most appropriate and efficient cooling solution.

9- Advantages of Dry Type Transformers

Dry-type transformers offer several advantages over their oil-filled counterparts. They are more environmentally friendly since they don’t contain any oil, which can be hazardous to the environment. They are also more fire-resistant and safer to use in high-risk areas such as hospitals, schools, and airports. They also need less maintenance, last longer, are smaller and lighter, and have a longer life span.

10- Applications of Dry Type Transformers

Dry-type transformers are used in a wide range of applications, including in commercial and industrial settings. They are commonly used in buildings, data centers, and manufacturing plants. They are also used in renewable energy applications, such as solar and wind power systems.

11- FAQs

Q1. Can a dry type transformer be used in outdoor applications?

A1. Yes, dry type transformers can be used in outdoor applications, provided they are properly protected from environmental factors.

Q2. What is the life expectancy of a dry type transformer?

A2. The life expectancy of a dry type transformer is approximately 30 years, but with proper maintenance, it can last much longer.

Q3. What are the disadvantages of a dry type transformer?

A3. The main disadvantage of a dry type transformer is that it has a lower short-circuit strength compared to oil-filled transformers.

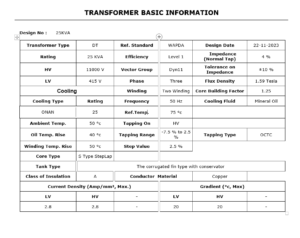

25KVA Distribution Transformer Design pdf

Introduction to Distribution Transformers Design Distribution Transformer Design plays a vital role in electrical power transmission and distribution systems. Among various transformer ratings, the 25KVA

Tunnel Lighting Design And Requirements

1. Introduction of Tunnel Lighting Design Tunnel lighting is critical to ensuring the safety, visibility, and efficient operation of road and transportation tunnels. The design

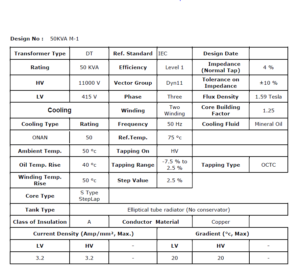

50 KVA Transformer Design complete calculation in Pdf

50 KVA transformer design complete calculation involves a comprehensive PDF sheet of calculations and considerations to ensure its efficiency, reliability, and adherence to safety standards.

What is a Single phase Transformer Construction and Its Working

Transformers, the unsung heroes of our electrical infrastructure, play a pivotal role in the seamless distribution of power. Among these, single-phase transformers stand out for

Unveiling the Secrets of Mastering Start Stop Motor Control Circuits

Do you want to learn more about mastering the Start Stop Motor Control Circuits? You can learn all the details about this vital part of

What is HiPot testing or Dielectric Withstand testing?

1.0 Introduction to HiPot Testing or Dielectric Withstand Testing HiPot testing, short for High Potential Testing, is a critical procedure used in the realm of

Leave a Reply