1-Introduction to High Voltage Switchgear

High voltage switchgear is essential to the control and distribution of electricity. It plays a crucial role in electrical systems by enabling the efficient and safe passage of electricity via high-voltage circuits.

High-voltage switchgear’s primary function is to regulate, safeguard, and isolate electrical equipment in a variety of settings, including power plants, businesses, and industrial sites. Switchgear safeguards the dependability and stability of electrical networks by utilizing complex procedures and cutting-edge technology, reducing the likelihood of interruptions and increasing operational effectiveness.

It is impossible to overestimate the significance of high voltage switchgear. It serves as a safety measure, averting electrical malfunctions and reducing any risks that can jeopardies the reliability of the power source. Switchgear facilitates continuous and uninterrupted power distribution, facilitating the seamless functioning of critical infrastructure and key services. It does this by properly managing voltage levels and isolating problematic components.

High voltage switchgear is essentially the embodiment of robustness, safety, and dependability in electrical engineering. Its importance in contemporary culture, where having access to dependable energy is essential for everyday ease, economic growth, and technological innovation, is highlighted by its role in preserving the integrity of power systems

The basics of high voltage switchgear become crucial as we go deeper into the field of electrical engineering. Switchgear represents the confluence of innovation, efficiency, and dependability from its fundamentals to its complex operations, propelling the progress of power distribution systems towards a more promising and sustainable future.

2- Importance of High Voltage Switchgear

It is impossible to overestimate the significance of high voltage switchgear in electrical systems. A vital element in ensuring the dependable and secure distribution of electrical power across several networks and applications is high voltage switchgear.

Controlling the flow of electricity in high voltage circuits is one of the main purposes of high voltage switchgear. It serves as a safeguard, able to isolate malfunctioning machinery and stop electrical problems from spreading across the entire system. Switchgear minimizes disturbances and preserves the integrity of the power supply by quickly stopping the flow of electricity under abnormal circumstances like overloads or short circuits.

High voltage switchgear is also essential for guaranteeing the security of people and property in electrical facilities. Switchgear helps reduce the risks of electrical accidents and injuries by separating malfunctioning components and offering distinct points of separation for maintenance work. This makes the working environment safer for technicians and operators.

Furthermore, the general stability and resilience of electrical grids are influenced by the dependability and effectiveness of high voltage switchgear. Robust switchgear systems are vital in environments where a continuous power supply is required, such as critical infrastructure, industrial facilities, and healthcare institutions.

Furthermore, high voltage switchgear facilitates load control and voltage regulation, which allows power distribution networks to be optimized. Operators may ensure maximum performance and efficiency by strategically deploying switchgear equipment to balance the electrical demand across different grid segments.

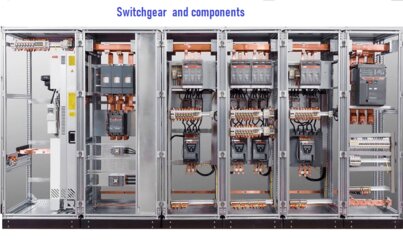

3- Components of High Voltage Switchgear

High voltage switchgear is made up of a number of crucial parts, each of which has a specific function in the distribution, protection, and control of electrical power. It is essential to appreciate these elements in order to understand how high voltage switchgear systems function and operate:

- Circuit Breakers: The main parts of high-voltage switchgear are circuit breakers are in charge of stopping the flow of electricity in the case of anomalies such as overloads or short circuits. They serve as automatic switches, cutting off the malfunctioning circuit to guard against equipment damage and guarantee the security of the electrical system.

- Disconnectors: Also referred to as isolators, disconnectors offer a way to physically isolate particular electrical network segments for upkeep or repairs. Disconnectors, in contrast to circuit breakers, perform as vital safety devices during maintenance tasks but do not normally stop current flow.

- Current Transformers: A key component in determining how much electrical current is passing through a system is a current transformer (CT). They provide vital information for load control, fault detection, and power quality analysis by converting large currents into levels that are manageable for precise measurement and monitoring.

- Voltage Transformers: VTs, or voltage transformers, are essential for monitoring voltage levels in the electrical grid. Voltage transformers, like current transformers, ensure the system’s safety and dependability by stepping down high voltages to levels appropriate for measurement and monitoring.

- Relays: In high voltage switchgear, relays safeguard against abnormal circumstances like overcurrent, under voltage, or phase imbalances. Relays are designed to isolate the impacted circuit and stop possible harm or risks by activating circuit breakers or other safety measures when activated.

- Control Panels: The monitoring and control equipment required for efficiently controlling and running the switchgear system is housed in control panels. They give operators up-to-date knowledge about the condition of the electrical grid, allowing them to decide wisely and respond appropriately when necessary.

- Busbars: Within the switchgear assembly, busbars are conductive bars or strips that act as electrical highways to help distribute power. They facilitate the smooth passage of electricity between different portions of the system by connecting diverse devices including transformers, disconnectors, and circuit breakers.

- Enclosures: High voltage switchgear’s internal components are shielded and insulated from the elements by enclosures from elements like moisture, dust, and temperature changes. They guarantee the switchgear’s dependable and safe performance under a variety of operating circumstances.

Manufacturers and operators of high voltage switchgear may provide sturdy and dependable solutions for the effective control and distribution of electrical power by combining these elements into a cohesive and well-designed system. They are essential to the functioning, dependability, and safety of the switchgear system and are a necessary part of any contemporary electrical infrastructure.

4- Types of High Voltage Switchgear

High-voltage switchgear is available in a variety of designs, each designed to meet the demands of different applications, environments, and operational circumstances. Selecting the best high-voltage switchgear for a given electrical system requires an understanding of the many types of switchgear. The main categories are as follows:

- Air-Insulated Switchgear (AIS): This type of switchgear uses ambient air to act as an insulator between live components and conductors. When there is enough room and ambient air usage is permitted by environmental factors, it is frequently utilized in both indoor and outdoor setups. AIS switchgear is a well-liked option for medium to low voltage applications because of its cost-effectiveness, ease of maintenance, and straightforward design.

- Gas-Insulated Switchgear (GIS): To offer better insulation and arc-quenching capabilities, gas-insulated switchgear uses Sulphur hexafluoride (SF6) gas or other insulating gases. Due to its small design, GIS switchgear is appropriate for installations with tight space constraints or environmental regulations. Compared to AIS switchgear, it provides improved dependability, lower maintenance requirements, and increased operational safety, which makes it perfect for high voltage applications in cities, substations, and industrial sites.

- Hybrid Switchgear: To maximise efficiency and economy, hybrid switchgear blends the capabilities of both AIS and GIS technologies. It usually combines gas-insulated modules with air-insulated components, providing a compromise between space-saving, flexibility, and dependability. Because hybrid switchgear is flexible and can adjust to different operating environments, it is appropriate for a wide range of applications where having a mix of functions is preferred.

- Solid Insulated Switchgear: To offer insulation and defence against electrical problems, solid materials like silicone rubber or epoxy resin are used in solid insulated switchgear. It ensures long-term dependability and durability by providing outstanding resistance to external elements, moisture, and pollutants. In tough settings, outdoor installations, and specialised applications where conventional insulation techniques would be unfeasible or inefficient, solid-insulated switchgear is frequently utilised.

- Switchgear Insulated with Oil:

High voltage components are insulated using mineral oil or synthetic dielectric fluids in oil-insulated switchgear. Due to safety standards and environmental concerns, oil-insulated switchgear is becoming less prevalent; nonetheless, it still has good dielectric qualities, thermal stability, and self-healing capabilities. It is usually found in industrial buildings, older systems, and substations where replacement or upgrading may be difficult.

Every kind of high voltage switchgear has unique uses, restrictions, and benefits. To guarantee maximum performance and dependability in electrical networks, engineers and operators may make well-informed decisions about the selection, installation, and maintenance of switchgear systems by being aware of the traits and capacities of each kind.

6- Applications of High Voltage Switchgear

High voltage switchgear is used in a wide range of sectors and industries where effective and dependable power distribution is crucial. It is invaluable in a variety of situations because to its toughness and adaptability, including:

- Power Generation facilities: To regulate and distribute electricity produced by turbines, generators, or renewable energy sources, power generation facilities employ high voltage switchgear. It guarantees the smooth transfer of electricity from the producing plant to the local distribution networks or the transmission grid.

- Transmission and Distribution Grids: The foundation of transmission and distribution networks is high voltage switchgear, which facilitates the effective transport of energy across vast distances and voltage ranges. In order to satisfy consumer and industry expectations, it aids in managing voltage levels, balancing loads, and maintaining grid stability.

- Industrial Facilities: To power the machinery, tools, and procedures necessary for operations, production, and manufacture, industries rely on high voltage switchgear. Switchgear minimises downtime and maximises efficiency in industries including mining, petrochemicals, manufacturing, and automotive by ensuring a steady and dependable power supply.

- Commercial Buildings and Infrastructure: To distribute energy to lights, HVAC systems, lifts and other electrical loads, high voltage switchgear is utilised in commercial buildings, office complexes, retail malls and infrastructure projects. It guarantees the safety of both residents and guests and delivers dependable electricity delivery.

- Renewable Energy Installations: High voltage switchgear is necessary for integrating renewable energy systems into the grid, as the use of renewable energy sources including solar, wind, and hydroelectric power grows. Switchgear facilitates seamless integration with the current power infrastructure and aids in managing variations in the output of renewable energy.

- Data Centers and Telecommunications: In order to sustain vital operations and communications networks, data centers and telecom facilities need a constant power supply. High voltage switchgear guarantees dependable power distribution and backup systems to keep services running smoothly, avoid data loss, and stop network outages.

- Transportation and Infrastructure: Electricity for lighting, signaling, traction systems, and terminal operations is provided by high voltage switchgear, which also powers metro networks, airports, and seaports. Switchgear supports seamless and continuous operations by ensuring the efficiency, safety, and dependability of the transportation infrastructure.

- Emergency and Critical Services: In times of emergency, blackout, or natural catastrophe, high voltage switchgear is important to the operation of emergency services, hospitals, military sites, and disaster response centers. Switchgear guarantees that vital equipment, lights, and life support systems will always have electricity.

7- Advantages of High Voltage Switchgear

High voltage switchgear is essential to contemporary electrical systems due to its many benefits. The following are some main advantages:

- Reliability: By efficiently regulating the flow of energy and isolating problematic circuits, high voltage switchgear assures dependable power distribution. In essential applications, the danger of electrical failures, interruptions, and downtime is reduced by its sturdy design and reliable functioning.

- Safety: By guarding against electrical risks including overload, short circuits, and overvoltage situations, switchgear improves safety. It has safety measures like relays, circuit breakers, and isolators to isolate malfunctioning equipment and stop mishaps or harm to people or property.

- Efficiency: Through load balancing, voltage level management, and the reduction of energy losses during transmission and distribution, high voltage switchgear maximises the efficiency of electrical systems. It guarantees a steady flow of power with little waste, which enhances system efficiency and promotes energy saving.

- Flexibility: Switchgear may be designed and configured in a flexible manner to suit a range of applications, voltage levels, and environmental factors. It may be customised to meet unique needs, enabling interaction with current infrastructure, modular extension, and customisation.

- Space-saving: Compared to conventional air-insulated switchgear (AIS), modern high voltage switchgear designs, such as gas-insulated switchgear (GIS), provide compact and space-saving alternatives. GIS technology is perfect for urban installations and cramped places because it can achieve higher voltage ratings and better power density in smaller footprints.

- Ease of Maintenance: High voltage switchgear is made with easily accessible parts, facilities for diagnostics, and the ability to do predictive maintenance. Frequent testing, service, and inspections aid in the early detection of any problems and the avoidance of expensive malfunctions or outages.

- Longevity: Switchgear is designed to endure severe weather, fluctuating temperatures, and mechanical strains, guaranteeing its dependability and robustness over an extended period of time. Long-lasting coatings, sturdy construction methods, and high-quality materials all add to the durability of switchgear installations.

- Compatibility with Renewable Energy: High voltage switchgear may be easily integrated into the electrical system to incorporate renewable energy sources including hydroelectric, solar, and wind power. It ensures grid stability and dependability by facilitating the smooth integration of intermittent renewable energy supply with traditional power sources.

- Scalability: Switchgear systems may be modified or enlarged to accommodate changing load profiles, increasing demand, or advances in technology. Easy scalability is made possible by modular designs and standardised components, which don’t require major interruptions to the infrastructure.

8- Challenges and Considerations

High voltage switchgear has many benefits, but it also has drawbacks that need to be taken into account in order to guarantee dependability, safety, and maximum performance. Among the major obstacles and things to think about are:

- Maintenance Requirements: To guarantee correct functioning and avert potential failures, high voltage switchgear has to be maintained on a regular basis. Inspection, testing, cleaning, and lubrication are examples of maintenance operations that are necessary to find problems early on and fix them before they become serious ones.

- Environmental conditions: Extremes in temperature, humidity, corrosive materials, and pollution are just a few of the environmental conditions that switchgear installations must contend with. Environmental factors can affect the lifespan and functionality of switchgear components, thus proper precautions and maintenance procedures are required.

- Safety Hazards: Because high voltage switchgear contains electrical currents, high voltages, and the possibility of an arc flash, it presents inherent safety risks. Sufficient safety measures, instruction, personal protective equipment (PPE), and isolation techniques are necessary to reduce the likelihood of electrical mishaps and worker injuries.

- Operational Complexity: Switchgear systems, particularly in large-scale installations with numerous components, circuits, and control mechanisms, can be difficult to run and maintain. Comprehensive training and experience are necessary for operators and maintenance staff to guarantee correct handling, troubleshooting, and emergency response protocols.

- Reliability and Availability: In important applications and industries, switchgear reliability and availability are crucial for guaranteeing a continuous power supply and reducing downtime. To improve availability and dependability, design factors, component quality, redundancy controls, and predictive maintenance plans are crucial.

- Cybersecurity Risks: High voltage switchgear is susceptible to cybersecurity risks including malware, hacking, and unauthorised access due to the growing digitalization and interconnectedness of electrical infrastructure. Encryption techniques, network segmentation, and strong cybersecurity procedures are required to safeguard switchgear systems against cyberattacks and data breaches.

- Regulatory Compliance: Industry associations and regulatory bodies have established rules, regulations, and recommendations that high voltage switchgear must follow. To guarantee adherence to best practices and regulatory requirements, compliance requirements may include safety standards, environmental restrictions, performance criteria, and certification procedures.

- Financial Factors to Take Into Account: When making a selection, one should consider the upfront costs associated with purchasing and installing high-voltage switchgear as well as continuing maintenance and operating costs. Financial considerations, lifespan cost evaluations, and cost-benefit analyses are crucial for determining whether switchgear investments are economically viable and sustainable in the long run.

9- Maintenance and Safety Practices for high voltage switchgear

The maintenance and safety protocols of high voltage switchgear systems are critical to their maximum performance and dependability. Routine maintenance procedures are necessary to detect any problems early and avoid expensive malfunctions or outages. These procedures should include planned inspections, testing, and preventative actions. Checking for loose connections, examining insulation, lubricating moving parts, and testing safety devices to make sure they function properly in unusual circumstances are some examples of maintenance duties. Furthermore, it is essential to follow stringent safety procedures in order to reduce the dangers related to high voltage activities. This entails giving staff members thorough training, enforcing lockout-tagout protocols during maintenance tasks, and making sure the proper personal protective equipment (PPE), such as insulated gloves, goggles, and arc flash suits, is used. To notify staff members of potential risks and guarantee safe working conditions, further safety measures that should be included include warning systems, barriers, and clear signs. Through the use of rigorous maintenance and safety protocols in switchgear operations, operators may reduce risks, improve dependability, and protect staff and equipment from mishaps and harm.

10- Environmental Impact and Sustainability

High voltage switchgear systems’ design, operation, and lifetime management increasingly take sustainability and environmental effect into account. Energy consumption, greenhouse gas emissions, and resource depletion are only a few of the negative environmental effects that switchgear manufacture, installation, and operation may have. Therefore, it is crucial to reduce the environmental impact of switchgear installations in order to lessen detrimental effects on ecosystems and public health. The implementation of sustainable practices, such as the use of environmentally friendly materials, energy conservation, and resource optimisation, is crucial for fostering environmental stewardship and mitigating the consequences of climate change. Switchgear component recycling and disposal at the end of their useful lives also need to be carefully considered in order to reduce waste production and optimise resource recovery. To create and execute ecologically friendly solutions, such as innovative product design, recycling programmes, and pollution control measures, manufacturers, operators, and regulatory organisations must work together. For both current and future generations, the switchgear business can help create a cleaner, healthier planet by putting sustainability and environmental impact reduction first.

11- Conclusion

To sum up, high voltage switchgear is an essential component of contemporary electrical infrastructure, enabling effective power distribution and control for a wide range of uses and sectors. Switchgear systems have many benefits, but they also come with a number of drawbacks, from sustainability and environmental impact to maintenance needs and safety risks. In order to overcome these obstacles, switchgear installation manufacturers, operators, regulators, and industry stakeholders must work together to improve environmental stewardship, safety, and dependability. In order to guarantee the continuous dependability, resilience, and sustainability of the electrical infrastructure and thereby promote economic development, environmental preservation, and social welfare in the future, the switchgear industry must prioritise proactive maintenance techniques, strict safety regulations, and sustainable design principles.

12- FAQs

What is high voltage switchgear?

High voltage switchgear is a vital component in electrical systems that controls and regulates the flow of electricity in high voltage circuits. It comprises various components such as circuit breakers, disconnectors, transformers, and control panels to ensure the safe and reliable distribution of power. High voltage switchgear comes in different types and is essential for protecting against electrical faults and maintaining the integrity of the power supply.

How does high voltage switchgear work?

High voltage switchgear controls electricity flow in high voltage circuits by using components like circuit breakers and disconnectors. It detects and responds to faults, such as overload or short circuits, by isolating the affected area to prevent damage and ensure safety. Additionally, it regulates voltage levels and current flow for efficient power distribution. Overall, high voltage switchgear plays a crucial role in maintaining the stability and reliability of electrical systems.

What are the main components of high voltage switchgear?

The main components of high voltage switchgear include circuit breakers, disconnectors, current transformers, voltage transformers, relays, control panels, busbars, and enclosures. These components work together to control the flow of electricity, protect the system from faults, measure current and voltage levels, and ensure safe and efficient power distribution.

Leave a Reply