Motor Control Panel Components | Low Voltage Components

Electric motors are used in various applications, from small household appliances to heavy machinery. To ensure the efficient and safe operation of electric motors, motor control panels are used. Motor control panels consist of various components that are responsible for controlling the operation of electric motors. In this article, we will discuss the different components of motor control panels, specifically low voltage components.

Introduction

Motor control panels are critical components in the operation of electric motors. They provide an easy and safe way to control the speed, torque, and direction of electric motors. Low voltage components are an essential part of motor control panels as they regulate the power supply to the motor. In this article, we will discuss the different low voltage components of motor control panels and their functions.

What are Motor Control Panels?

Motor control panels are electrical devices that control the operation of electric motors. They consist of various components that work together to regulate the speed, torque, and direction of the motor. There are two types of components in motor control panels: low voltage components and high voltage components. Low voltage components regulate the power supply to the motor, while high voltage components regulate the power supply to the motor starter.

Motor Control Panel Components of that operate at low voltage

1. Circuit Breakers

Circuit breakers are devices that protect the motor from overloading and short circuits. If the motor’s rated capacity is exceeded, they interrupt the current flow. Motor control panels usually have circuit breakers on the input side.

2.Contactors

Contactors are switches that turn the motor on and off. They are usually operated by a low voltage control circuit and are connected to the power supply and the motor. Contactors are designed to handle the high current of the motor and are located on the output side of the motor control panel.

3. Overload Relays

Overload relays protect the motor from overloading. They are connected to the contactor and monitor the current flow to the motor. If the current exceeds the rated capacity of the motor, the overload relay will open the contactor, stopping the motor.

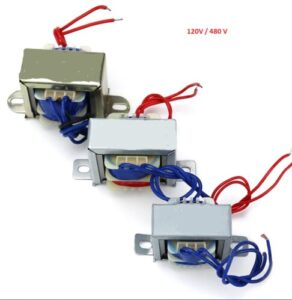

4. Control Transformers

Control transformers are used to provide low voltage power to the control circuit. They step down the voltage from the main power supply to a lower voltage suitable for the control circuit. A motor control panel’s input side contains control transformers.

5. Pilot Devices

Pilot devices are switches and indicators that control and monitor motor operation. They include push buttons, selector switches, and indicator lights. Pilot devices are usually connected to the control circuit and are located on the front panel of the motor control panel.

6. Terminal Blocks

Motor control panels use terminal blocks to connect their components. They provide a safe and easy way to make connections between components. Terminal blocks are usually located on the inside of the motor control panel.

7.Fuses

Fuses are devices that protect the motor from overloading and short circuits. They are designed to interrupt the current flow when the current exceeds the rated capacity of the motor. Fuses are usually located on the input side of the motor control panel.

8. Power Supplies

A power supply is an electronic device that converts electrical energy from one form to another in order to power other electronic devices. It typically takes in AC voltage from a wall outlet and converts it to a lower DC voltage that can be used to power things like computers, televisions, and other electronics. Power supplies are used in a wide variety of applications, from small electronic devices to large industrial machines. They come in many different types and sizes, and can be designed to provide different levels of power output depending on the needs of the device being powered.

9. Surge Suppressors

Surge suppressors are devices that protect the motor and the motor control panel from voltage spikes and surges. As a result, excess voltage is absorbed and dissipated, preventing damage to the motor and its components.

Applications of Motor Control Panel Component

Control panels for motors are used in a variety of applications, including:

- HVAC systems

- Conveyor systems

- Pumping systems

- Manufacturing processes

- Elevators and escalators

- Robotics

- Compressors

- Water treatment plants

Benefits of Using Motor Control Panels

Using motor control panels offers several benefits, including:

- Improved efficiency and productivity

- Enhanced safety for operators and equipment

- Reduced maintenance and repair costs

- Extended lifespan of motors and equipment

- Reduced energy consumption and costs

- Easy and precise control of motor speed, torque, and direction

Maintenance of Motor Control Panels

Regular maintenance of motor control panels is essential to ensure their efficient and safe operation. Maintenance tasks may include:

- Checking for loose or corroded connections

- Inspecting and cleaning components

- Testing the operation of circuit breakers, contactors, and overload relays

- Lubricating moving parts

- Replacing worn or damaged components

Common Issues with Motor Control Panels

Some common issues that may arise with motor control panels include:

- Electrical shorts or faults

- Overloading or underloading of the motor

- Faulty contactors or relays

- Burned or damaged components

- Power supply issues

- Incorrect wiring or connections

Conclusion

In the operation of electric motors, motor control panels play an essential role. Low voltage components, in particular, play a critical role in regulating the power supply to the motor. Understanding the different components of motor control panels and their functions is essential for efficient and safe operation. Regular maintenance and inspection can help identify and address issues before they cause damage to the motor or the motor control panel.

FAQs

What is a motor control panel?

A motor control panel is an electrical device that controls the operation of electric motors.

What are low voltage components of motor control panels?

Low voltage components of motor control panels regulate the power supply to the motor and include circuit breakers, contactors, overload relays, control transformers, pilot devices, terminal blocks, fuses, power supplies, and surge suppressors.

What is the function of an overload relay?

An overload relay protects the motor from overloading by monitoring the current flow to the motor and opening the contactor if the current exceeds the rated capacity of the motor.

What are some common issues with motor control panels?

Common issues with motor control panels include electrical shorts or faults, overloading or underloading of the motor, faulty contactors or relays, burned or damaged components, power supply issues, and incorrect wiring or connections.

What are the benefits of using motor control panels?

Using motor control panels offers several benefits, including improved efficiency and productivity, enhanced safety for operators and equipment, reduced maintenance and repair costs, extended lifespan of motors and equipment, reduced energy consumption and costs, and easy and precise control of motor speed, torque, and direction.

Leave a Reply