Edison batteries, sometimes referred to as nickel-iron batteries, are proof of the long-lasting influence of Thomas Edison’s inventions. Even though they were among the first technologies for rechargeable batteries, they are still relevant in contemporary applications, especially in renewable energy systems.

1- Introduction to Nickel-Iron Batteries

The nickel-iron battery, or Edison battery, is a benchmark in energy storage technologies. This type of battery, which Thomas Edison, a well-known inventor, invented in the early 1900s, is a revolutionary advancement in the field. In contrast to traditional lead-acid batteries that were common at their invention, the nickel-iron battery has a unique composition and working mechanism that provide special benefits in various applications.

Edison created a battery that could outperform and outlast its competitors due to his relentless pursuit of invention. The outcome was the nickel-iron battery, distinguished by its extended lifespan, resilience, and environmentally beneficial qualities. The nickel-iron battery has remained relevant over time despite developments in battery technology, especially in niche markets where its unique attributes are highly valued.

The nickel-iron battery, which has left a lasting impression on energy storage technologies, epitomises the spirit of innovation and sustainability. We uncover the fantastic journey of this unique creation as we investigate its complexities and uses, opening the door to a greater comprehension of its relevance in the contemporary world.

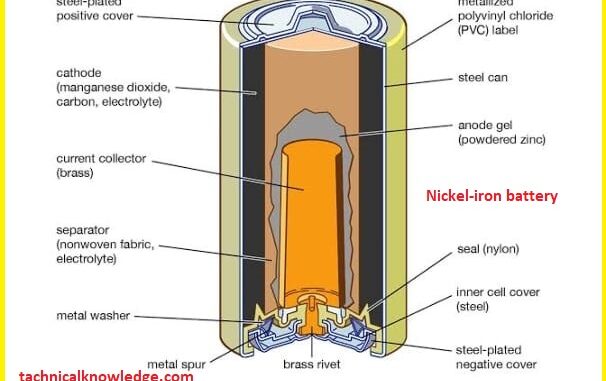

2- Understanding the Composition of Nickel-Iron Battery

Understanding the nickel-iron battery’s composition is essential to understanding its inner workings and distinctive features. In contrast to conventional lead-acid batteries, which use sulfuric acid electrolytes and lead plates, the nickel-iron battery uses a unique material combination to maximise longevity and performance.

The nickel-iron battery comprises three main parts: an alkaline electrolyte solution, iron, and nickel electrodes. Let’s examine each of these components in more detail:

- Nickel Electrodes: One of the essential parts of the nickel-iron battery is the nickel electrodes. Usually made of porous nickel plaques or tubes, these electrodes offer a significant surface area for electrochemical processes. During charging and discharging cycles, nickel electrodes are essential for enabling the storage and release of electrical energy.

- Iron Electrodes: The nickel-iron battery uses iron and nickel electrodes. Like nickel electrodes, iron electrodes are made to maximize surface area and improve electrochemical reactions. For the fabrication of electrodes, iron is a dependable and plentiful material that enhances the overall performance and durability of the battery.

- Alkaline Electrolyte Solution: Potassium hydroxide (KOH) is nickel-iron batteries’ most often used alkaline electrolyte solution. This alkaline electrolyte helps the ions move between the nickel and iron electrodes during the charge and discharge cycles. The electrolyte’s alkaline composition enhances the battery’s stability and safety, which also facilitates effective energy transmission throughout the system.

These three parts are kept safe from the elements and given structural support by being contained in a sturdy steel container. Together with preventing leaks and corrosion over time, the steel casing also aids in preserving the battery’s integrity.

The nickel-iron battery differs from other battery types in that it has an alkaline electrolyte solution combined with iron and nickel electrodes, giving it unique qualities, including durability, resilience, and environmental sustainability. Knowing the components of the nickel-iron battery is essential to understanding its working principles and investigating its wide range of applications in different sectors.

3- Working Principles of Nickel-Iron Battery

The reversible electrochemical reaction between the nickel and iron electrodes submerged in an alkaline electrolyte solution is the basis for the operation of the nickel-iron battery, sometimes referred to as the Edison Battery.

The nickel-iron battery is subjected to an external electrical current during charging. Within the battery, this current initiates a chemical process that reduces iron oxide (Fe2O3) at the iron electrode and oxidises nickel hydroxide (Ni(OH)2) at the nickel electrode. Chemical bonds are formed within the battery due to these reactions, storing energy.

The following is a representation of the oxidation process at the nickel electrode:

Ni(OH)2 → H2O + e-NiOOH

In the meantime, the iron electrode’s reduction process moves along as follows:

Fe2O3 → 2Fe(OH) + 3H2O + 6e-3.

When the Nickel Iron Battery is charged, iron oxide changes into iron hydroxide at the negative electrode (cathode) and nickel hydroxide changes into nickel oxyhydroxide at the positive electrode (anode). This is how the battery stores electricity.

The opposite processes occur during discharge when the battery powers an external load. Iron hydroxide at the negative electrode takes in electrons and ions, while nickel oxyhydroxide at the positive electrode releases them. This electron flow can power a variety of systems or devices with an electric current.

The following briefly describes the discharge reactions:

With NiOOH + H2O + e at the positive electrode (anode), Ni(OH)2 + OH is produced. – At the cathode, or negative electrode:

Fe(OH)3 + 3H2O + 6e- → Fe2O3

The practical storage and release of electrical energy is made possible by the reversible electrochemical processes found in the nickel-iron battery. The battery’s innate reversibility contributes to its reputation for endurance and durability by enabling it to go through several cycles of charging and discharging without experiencing any noticeable deterioration.

The nickel-iron battery’s operation highlights how well-suited it is for a variety of uses, including industrial use, backup power systems, and the storage of renewable energy. When durability and robustness are crucial, its robust construction and dependable operation make it an appealing option.

4-Characteristics of Nickel-Iron Battery

The nickel-battery, also called the Edison Battery, differs from other battery types in several ways. Comprehending these attributes is vital in assessing their appropriateness for diverse uses and drawing comparisons with substitute energy storage remedies. The nickel-iron battery has the following essential properties:

- Durability: The remarkable durability of the nickel-iron battery is one of its most noteworthy features. In contrast to many other battery types, nickel-iron batteries can endure several cycles of charge and discharge without suffering appreciable performance deterioration. The battery’s resistance to corrosion and sturdy electrode structure are responsible for its longevity.

- Longevity: Nickel-iron batteries have a well-known extended life. These batteries are an affordable long-term investment because they may survive for several decades with the proper upkeep and care. Their endurance over several charge and discharge cycles without sacrificing functionality adds to their lifetime.

- Wide Temperature Range: The capacity of nickel-iron batteries to function well across a broad temperature range is another one of their qualities. Nickel-iron batteries resist adverse weather conditions, unlike specific battery chemicals that might malfunction at extremely high or low temperatures.

- Safety: Nickel-iron batteries are considered both ecologically benign and safe. Nickel-iron batteries are non-toxic and non-flammable, unlike lead-acid batteries, which contain hazardous ingredients and release poisonous fumes. This lessens the danger to human health and the environment and makes them safer to handle and dispose of.

- Low Maintenance: Nickel-iron batteries require less maintenance than many other batteries. They are free of problems like stratification and sulfation frequently linked to lead-acid batteries. To guarantee peak performance, routine inspections of the electrolyte levels and electrode quality are usually adequate.

- Gradual Rates of Charging and Discharging: Nickel-iron batteries frequently have slower charging and discharging speeds despite their remarkable lifetime and resilience compared to many contemporary battery technologies. This feature could make them less suitable for uses where quick energy transmission is necessary.

The nickel-iron battery’s qualities make it an appealing option for several uses where reliability, lifespan, and safety are crucial. Its dependability and environmental friendliness make it a top choice for off-grid power systems, renewable energy storage, and other specialised applications, even if it may not offer the highest energy density or the fastest charging speeds. The performance and capacities of nickel-iron batteries may be further improved as technology develops, increasing the range of possible applications for them.

5- Comparison with Other Battery Technologies

When contrasting the nickel-iron battery with other battery technologies, meaningful information may be learned about their advantages, disadvantages, and applicability for different uses. Even though every battery type is different, knowing these differences may help consumers make well-informed judgements based on their needs and requirements. The nickel-iron battery is contrasted with a few popular battery technologies here:

1- Battery made of lithium-ion:

Lithium-ion batteries are extensively utilised in renewable energy storage systems, electric automobiles, and consumer gadgets.

Thium-ion batteries can store more energy in a smaller, lighter package because they generally have a greater energy density than nickel-iron batteries.

– Lithium-ion batteries can be used in applications requiring quick energy transfer because of their quicker charging and discharging rates.

Lithium-ion batteries, however, would not last as long and might be more vulnerable to safety risks, including thermal runaway and fire dangers.

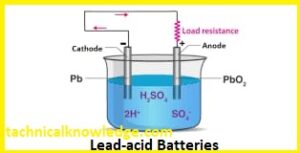

2- Lead-acid Batteries: For many years, lead-acid batteries have been utilised in industrial, automotive, and backup power settings.

Lead-acid batteries are less long-lasting and durable than nickel-iron batteries, particularly in deep-cycle applications.

Lead-acid batteries are less suited for limited weight and space since they are thicker and heavier than nickel-iron batteries.

On the other hand, lead-acid batteries have well-established recycling procedures and are reasonably priced.

3- Batteries with Flow:

One kind of rechargeable battery is a flow battery, which circulates electrolytes through the battery cells after being stored in external tanks.

Flow batteries are more flexible and scalable in energy storage capacity than nickel-iron batteries, making them suitable for grid-scale energy storage applications.

Flow batteries may tolerate deep discharges without suffering appreciable deterioration and may also have a long cycle life.

Flow batteries, however, could be less energy-efficient and have more significant initial expenditures than nickel-iron batteries.

4- Batteries using sodium ions:

A developing battery technology called sodium-ion batteries uses sodium ions rather than lithium as charge carriers.

Sodium-ion batteries may be more affordable and have a larger supply of raw materials than nickel-iron batteries, which might cut production costs and have a less negative environmental impact.

On the other hand, sodium-ion batteries are still in their infancy and might need to match nickel-iron batteries’ dependability and performance.

6- Applications of Nickel-Iron Batteries

Nickel Iron Batteries, sometimes called Edison Batteries, are used in various settings and sectors where their unique qualities are appreciated. Despite being an older technology, nickel-iron batteries are still helpful today because of their lifetime, resilience, and environmental sustainability. The following are some typical uses for nickel-iron batteries:

- Renewable Energy Storage: To store extra energy produced during periods of peak production, nickel-iron batteries are frequently employed in combination with renewable energy sources like solar panels and wind turbines. Nickel iron batteries are ideally suited for storing renewable energy for usage during low output or high demand because of their extended lifespan and deep cycle capacity.

- Off-Grid Power Systems: Nickel Iron Batteries offer a dependable energy storage option for off-grid power systems in isolated areas or places without connection to the primary power grid. These batteries can provide electricity when there is little or no generation by storing energy produced by solar panels, diesel generators, and other sources.

- Telecommunications: Cell towers, distant radio stations, and backup power systems for communication networks are just a few telecommunications-related applications that frequently employ nickel-iron batteries. Their resilience to severe weather and long lifespan make them perfect for providing dependable backup power in vital communication facilities.

- Railway Signalling and Signalling Systems: In the case of a power loss or outage, railway signalling systems rely on nickel-iron batteries as a backup power source. Their extended longevity and low maintenance needs make them affordable enough to guarantee that signalling apparatuses along train lines continue to function.

- Standby Power Systems: Emergency response centres, data centres, and hospitals rely on nickel-iron batteries as a backup power source. These batteries offer dependable backup power to keep critical processes running during a grid outage or power loss until regular power is restored.

- Mining and Industrial Applications: In isolated or off-grid areas, nickel-iron batteries are utilised to power machinery, lights, and other electrical systems in mining operations and industrial sites. They are ideal for demanding industrial settings due to their sturdy design and resilience to adverse working conditions.

- Hybrid and Electric Cars: Nickel-iron batteries have been investigated for use in hybrid and electric cars despite being less popular than other battery technologies like lithium-ion batteries. When it comes to applications where environmental effects and battery replacement costs are essential, their lifetime and durability make them a desirable choice.

- Energy Arbitrage and Peak Shaving: Nickel-iron batteries may be utilised for peak shaving and energy arbitrage in energy markets where power prices change daily. They can save money for customers and utilities by storing energy at low prices and discharging it during peak demand or higher power costs.

7- Environmental Impact and Sustainability

In the current era of increased environmental consciousness and concern, the sustainability and ecological effects of battery technologies, such as the nickel-iron battery, are crucial factors to consider. The assessment of several elements, including resource extraction, manufacturing methods, operating efficiency, and end-of-life disposal or recycling policies, is necessary to determine the environmental footprint of batteries.

The nickel-iron battery has a comparatively favorable environmental profile due to several factors, including:

- Non-Toxic Components: Nickel-iron batteries are made of comparatively non-toxic components compared to specific other battery chemicals, such as lead-acid batteries. The absence of harmful components reduces the risk of environmental contamination during battery manufacture, use, and disposal.

- Nickel-iron batteries have a high degree of recyclable content. Recycling procedures can be utilised to separate and reuse the iron and nickel electrodes and the alkaline electrolyte solution. Recycling contributes to the overall sustainability of the environment by lowering the need for raw materials, saving energy, and minimising waste.

- Longevity and Durability: Over time, fewer batteries will need to be produced and disposed of due to nickel-iron batteries’ long lifespan and durability. When properly cared for, nickel-batteries can endure for several decades, reducing the need for frequent replacements and the resulting environmental effects.

- Less Carbon Footprint: Although nickel-iron batteries may not have the same energy density as other more recent battery technologies, they can nonetheless have a minimal environmental effect throughout their lifetime. By facilitating the integration of clean energy sources into the grid, nickel-iron batteries, when utilized in renewable energy storage systems, help reduce greenhouse gas emissions.

- Minimal chance of thermal runaway: Nickel-iron batteries have fewer safety problems than some lithium-ion batteries, which can be vulnerable to thermal runaway and fire dangers in specific situations. This feature lowers the possibility of environmental harm in the case of battery problems and improves their ecological safety.

8- Disadvantages of Nickel-Iron Batteries

While nickel-iron batteries have many benefits, they also have several drawbacks that might make them unsuitable for some uses. It is essential to comprehend these disadvantages to assess the effectiveness and usefulness of nickel-iron batteries. The following are a few drawbacks of nickel-iron batteries:

- Lower Energy Density: When compared to other battery technologies, such as lithium-ion batteries, nickel-iron batteries sometimes have a lower energy density. This implies that bigger battery banks may be needed for applications requiring a higher energy storage capacity because they can store less energy per unit volume or weight.

- Slower Rates of Charging and Discharging: In comparison to many other battery types, nickel- iron batteries often have slower charging and discharging rates. For applications like electric cars or high-power backup systems that need fast charging or discharging, there might be better options than this slower rate of energy transfer.

- more significant initial cost: Compared to certain newer battery technologies or conventional lead-acid batteries, the initial cost of nickel-iron batteries may be more critical. Although the lifespan and durability of nickel-iron batteries result in long-term cost advantages, some users may be discouraged by the initial outlay, especially in applications where cost is a concern.

- Big Footprint: Nickel iron batteries could take up more room than batteries with a better energy density. In situations with a shortage of space or a preference for small battery designs, this bigger footprint may be a drawback.

- Limited Availability: Nickel-iron batteries could be more complex than widely used battery technologies like lithium-ion batteries. The possibilities for finding and buying nickel iron batteries may be restricted due to this limited availability, especially in some areas or marketplaces.

- Weight: Compared to other battery types, nickel-iron batteries tend to be heavier, which may be an issue in applications like electric cars or portable devices where weight is essential.

- Voltage fluctuation: When compared to other battery types, nickel iron batteries show more voltage fluctuation during discharge. In specific applications, this unpredictability could require the installation of voltage control circuitry to provide steady and reliable power output.

Even though these drawbacks could be problematic in some situations, it’s crucial to balance them with nickel-iron batteries’ unique benefits and features. For many applications where these attributes are essential, nickel iron batteries are the better option because their strength, lifespan, and environmental sustainability frequently exceed these drawbacks.

9- Maintenance and Care of Nickel Iron Batteries

Maintenance of a nickel-iron is essential to guarantee nickel-iron battery durability, dependability, and peak performance. Increase the longevity and efficiency of nickel-iron batteries by following recommended maintenance procedures. The following are some vital pointers for handling and preserving nickel iron batteries:

- Regular Electrolyte Inspection: Monitor the battery cells’ electrolyte levels regularly. To enable appropriate electrochemical reactions, ensure the electrolyte covers the plates sufficiently. Add distilled water to keep the electrolyte at the suggested concentration as necessary.

- Electrode Cleaning: Check the electrodes for buildup or corrosion regularly. Wash them with distilled water and baking soda to maintain the electrodes’ maximum conductivity and remove deposits. Refrain from using anything abrasive that might harm the electrodes.

- Equalisation Charging: To maintain a balance in the battery cells’ charge levels, occasionally carry out equalisation charging. In addition to ensuring consistent performance throughout the battery bank, equalisation charging helps avoid cell imbalance. Regarding the number of equalisation charging cycles and their length, according to the manufacturer’s instructions,.

- Temperature Control: Keep the batteries within the ideal temperature range to ensure optimal performance. Extreme temperatures should not be applied to nickel-iron batteries, which may reduce their lifespan and efficiency. Place the batteries in a location with sufficient ventilation and temperature control.

- Appropriate Charging Procedures: To avoid overcharging or undercharging the batteries, use a proper charging method with voltage and current control. To guarantee effective charging and prevent battery damage, adhere to the suggested charging guidelines supplied by the battery manufacturer.

- Routine Inspections: Check the battery terminals, connections, and casing regularly for leaks, corrosion, or other issues. To stop future degradation, tighten weak connections and replace or repair broken parts as soon as possible.

- Safety Measures: Take caution when using nickel-iron batteries since they contain corrosive electrolytes that can burn or irritate the skin. Before handling batteries or electrolyte solutions, put on the proper safety equipment, such as goggles and gloves. Adhere to industry standards and the manufacturer’s safety instructions.

- Documentation and Record-Keeping: Keep thorough records of all maintenance-related activities, such as dates of inspections, test results, and completed maintenance procedures. Monitor the battery’s performance characteristics, including capacity, temperature, and voltage, to monitor its condition and spot any abnormalities or problems.

10- Conclusion

In summary, the nickel-iron battery, often called the Edison battery, is a fantastic illustration of sustainability and creativity in energy storage technologies. A vital substitute for conventional battery technologies, the nickel-iron battery has distinct qualities such as endurance, resilience, and environmental friendliness.

The nickel-iron battery, created by Thomas Edison at the beginning of the 20th century, has withstood the test of time, demonstrating its dependability and efficiency in various applications. The nickel-iron battery keeps proving its adaptability and durability in multiple settings, from electric cars to off-grid power options and renewable energy storage systems.

The safety and recyclability of the nickel-iron battery, together with its composition and operating principle, highlight its potential as a sustainable energy storage option in the future. For applications where longevity, environmental sustainability, and durability are critical, the nickel-iron battery is the go-to option, even though competing battery technologies may have specific benefits in terms of energy density or charging speeds.

The nickel-iron battery can potentially be a key player in the shift to a cleaner and more sustainable energy landscape as technology develops and environmental concerns grow. Its performance, efficiency, and cost-effectiveness are being further improved via ongoing research and development, which should open up new applications for it in developing markets and sectors of the economy.

11- FAQs

How long do nickel-iron batteries last?

Nickel-iron batteries have a lifespan of up to 20–30 years under normal operating conditions, making them one of the longest-lasting battery technologies available.

Are nickel-iron batteries suitable for extreme temperatures?

Yes, nickel-iron batteries exhibit excellent performance across a wide temperature range, making them suitable for hot and cold climates.

Can nickel-iron batteries be used in electric vehicles?

While nickel-iron batteries offer durability and safety advantages, their lower energy density may limit their suitability for electric vehicle applications compared to lithium-ion batteries.

What are the main drawbacks of nickel-iron batteries?

The primary drawbacks of nickel-iron batteries include higher initial costs and lower energy density compared to some competing battery technologies.

How do nickel-iron batteries contribute to sustainability?

Nickel-iron batteries are highly sustainable due to their long service life, recyclability, and minimal environmental impact, making them an eco-friendly energy storage option.

Leave a Reply