Silica Gel Breather of Transformer: Enhancing Efficiency and Preventing Moisture Contamination

Introduction

Transformers are essential for the effective transmission and distribution of electrical power. It is crucial to shield them from moisture contamination in order to guarantee their top performance and longevity. A dependable solution, Silica Gel Breather successfully protects transformers by collecting moisture and preventing it from entering the system. In this article, we shall examine the specifics of silica gel breather, including its components, testing procedures that adhere to IEC standards, and its importance in transformer applications.

What is a Silica Gel Breather?

The Silica Gel Breather is a desiccant-filled device designed to maintain a moisture-free environment within a transformer. Its primary function is to absorb moisture from the air surrounding the transformer during the breathing process. By doing so, it prevents the entry of moisture into the transformer, ensuring its insulation integrity and overall efficiency.

Role in Maintaining Transformer Efficiency

Moisture contamination can have severe consequences for transformer performance. It can lead to insulation degradation, decreased dielectric strength, and an increased risk of electrical faults. Silica Gel Breather acts as the first line of defense, absorbing moisture and protecting the transformer from these issues. By maintaining a dry environment, it helps to sustain the transformer’s efficiency and extend its lifespan.

Working Principle of Silica Gel Breather

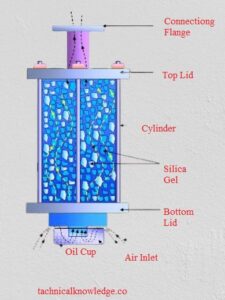

Silica Gel Breather operates on a simple yet effective working principle. It consists of a cylindrical container filled with silica gel, which is a highly porous and hygroscopic material. The breather is connected to the conservator tank of the transformer through a pipe. As the transformer undergoes heating and cooling cycles, the air inside expands and contracts, causing the breather to inhale and exhale air.

During the inhalation phase, the moist air from the atmosphere passes through the silica gel, which adsorbs the moisture. The dry air then enters the conservator tank, preventing any moisture from entering the transformer. In the exhalation phase, when the transformer cools down, the dry air from the conservator tank is exhaled back into the atmosphere.

Material Used in Silica Gel Breather

Silica Gel is the primary material used in Silica Gel Breathers due to its exceptional desiccant properties. It is a synthetically manufactured form of silicon dioxide (SiO2) that has a high affinity for moisture absorption. The porous structure of silica gel provides a large surface area for maximum moisture adsorption capacity.

Advantages of Silica Gel as a Desiccant

Silica Gel offers several advantages as a desiccant material in Silica Gel Breathers:

- High Adsorption Capacity: Silica Gel has a superior ability to adsorb moisture compared to other desiccants. It can adsorb up to 40% of its own weight in moisture, making it highly effective in maintaining a dry environment within the transformer.

- Regenerative Properties: One of the key advantages of Silica Gel is its ability to be easily regenerated and reused. When saturated with moisture, the Silica Gel can be heated to release the absorbed moisture, restoring its adsorption capacity.

- Non-Toxic and Environmentally Friendly: Silica Gel is non-toxic and chemically inert, making it safe to use in transformer applications. It does not produce any harmful by-products or emissions, ensuring environmental compatibility.

- Wide Operating Range: Silica Gel performs reliably over a wide range of temperatures and humidity levels. It remains effective even in extreme temperature conditions, making it suitable for various transformer environments.

Materials Used in the Construction of Silica Gel Breathers

To improve their functionality and durability, Silica Gel Breathers might also contain materials in addition to silica gel. Some common materials used in their construction are:

- Breather Body: The body of the breather is typically made of sturdy and corrosion-resistant materials such as stainless steel or high-grade plastic. This ensures the breather’s longevity and protection against external factors.

- Desiccant Chamber: The chamber that houses the Silica Gel is designed to allow proper airflow and moisture absorption. It is often constructed using materials that are resistant to moisture, corrosion, and mechanical damage.

Silica Gel Breather - Indicator System: Some Silica Gel Breathers feature an indicator system that provides visual indication of the desiccant’s saturation level. This allows easy monitoring of the breather’s condition and timely replacement of the Silica Gel when necessary.

Testing Methods as per IEC Standards

Testing Silica Gel Breathers is crucial to ensure their proper functioning and reliability in transformer applications. The International Electrotechnical Commission (IEC) has established standards for testing Silica Gel Breathers to maintain consistent quality and performance. These standards include:

- Desiccant Moisture Content: Testing the Silica Gel to determine its moisture content ensures that it is within the recommended range for effective moisture absorption.

- Desiccant Regeneration: The regeneration process of Silica Gel should be tested to verify its efficiency in releasing the absorbed moisture and restoring its adsorption capacity.

- Airflow Resistance: Silica Gel Breathers need to be tested for their airflow resistance to ensure that the breathing process is not hindered, allowing efficient exchange of air.

- Structural Integrity: Testing the structural integrity of the breather components ensures that they can withstand the operating conditions and mechanical stresses without failure.

Regular testing of Silica Gel Breathers as per the IEC standards helps to identify any issues and ensure their optimal performance in protecting transformers from moisture contamination.

Installation and Maintenance of Silica Gel Breather

Proper installation and regular maintenance are essential for the effective functioning of Silica Gel Breathers. Here are some important considerations:

Proper Installation Techniques

During installation, the following steps should be followed:

- Positioning: Silica Gel Breathers should be installed in an upright position, ensuring that the breather body is securely attached to Proper Installation Techniques

During installation, the following steps should be followed:

- Positioning: Silica Gel Breathers should be installed in an upright position, ensuring that the breather body is securely attached to the conservator tank. This allows proper airflow and easy access for maintenance.

- Mounting: The breather should be mounted at a height that allows sufficient clearance for breathing and to prevent any water ingress during heavy rainfall or flooding.

- Connection: Connect the breather to the conservator tank using a suitable pipe or hose. Ensure a tight and secure connection to prevent any air leakage.

- Ventilation: Provide adequate ventilation around the breather to allow for efficient airflow. Avoid obstructing the breather with any obstacles or coverings.

Regular Inspection and Maintenance

Regular inspection and maintenance are crucial to ensuring the optimal performance of Silica Gel Breathers. Here are some important maintenance practices:

- Visual Inspection: Regularly inspect the breather for any signs of physical damage, corrosion, or loose connections. Ensure that the breather body and desiccant chamber are clean and free from any contaminants.

- Desiccant Replacement: Monitor the saturation level of the Silica Gel using the indicator system or by visual inspection. When the Silica Gel turns from blue to pink, it indicates saturation and the need for replacement. Replace the desiccant with fresh Silica Gel following the manufacturer’s guidelines.

- Cleaning: If the breather becomes dirty or contaminated, clean it using a mild detergent solution and rinse thoroughly. Ensure that all components are completely dry before reassembling and reinstalling.

- Regeneration: If the Silica Gel breather is designed for regeneration, follow the manufacturer’s instructions to regenerate the desiccant when it becomes saturated. This process typically involves heating the Silica Gel to release the absorbed moisture.

By following proper installation techniques and conducting regular maintenance, the Silica Gel Breather can effectively protect transformers from moisture contamination, ensuring their optimal performance and longevity.

Benefits of Using Silica Gel Breather in Transformers

The use of Silica Gel Breathers in transformers provides several significant benefits:

- Prevention of Moisture Contamination: Silica Gel Breathers actively absorb moisture from the surrounding air, preventing it from entering the transformer. This helps to maintain a dry environment inside the transformer, protecting it from insulation degradation and other moisture-related issues.

- Extending Transformer Lifespan: By preventing moisture contamination, Silica Gel Breathers help to extend the lifespan of transformers. Moisture can accelerate the aging process and decrease the insulation’s effectiveness, leading to premature failure. Silica Gel Breathers mitigate these risks, allowing transformers to operate efficiently for a longer period.

- Enhancing Transformer Efficiency: Moisture in transformers can result in decreased dielectric strength and increased power losses. By maintaining a moisture-free environment, Silica Gel Breathers ensure optimal insulation performance and reduce energy losses, ultimately enhancing the overall efficiency of transformers.

Conclusion

Silica Gel Breathers play a vital role in protecting transformers from moisture contamination and maintaining their efficiency. By actively absorbing moisture and creating a dry environment, these devices help to prevent insulation degradation, extend transformer lifespans, and enhance overall performance. Following proper installation techniques, conducting regular maintenance, and adhering to testing methods as per IEC standards are essential to ensuring the effective operation of Silica Gel Breathers. Silica gel breathers are a dependable and affordable way to protect these important electrical assets in transformer applications.

FAQs

How does Silica Gel Breather work?

By actively absorbing moisture from the surrounding air while breathing, silica gel breathers function. The moist air passes through the Silica Gel, which adsorbs the moisture, ensuring that only dry air enters the transformer

Why is a silica gel breather used in transformers?

Transformers use silica gel breathers to keep their insulation from becoming contaminated by moisture and to preserve the transformer’s overall integrity. Moisture is a common enemy of transformers and can cause numerous issues such as insulation degradation, reduced dielectric strength, and an increased risk of electrical faults. Silica gel breathers play a crucial role in safeguarding transformers by actively absorbing moisture from the surrounding air.

When a transformer undergoes heating and cooling cycles, the air inside expands and contracts, resulting in a breathing process. During inhalation, the moist air from the atmosphere enters the Silica Gel Breather. The silica gel, which is a highly porous and hygroscopic material, adsorbs the moisture from the air, leaving it dry. The dry air then enters the conservator tank of the transformer, ensuring that no moisture enters the system.

By maintaining a moisture-free environment, Silica Gel Breathers prevent moisture from reaching the critical components of the transformer, such as the insulation materials and windings. This helps to preserve the insulation’s integrity, prevent insulation breakdown, and prolong the lifespan of the transformer. Additionally, by reducing moisture content, silica gel breathers minimize the risk of electrical faults and improve the overall efficiency of the transformer.

What is the color of Silica Gel in a dry condition?

In a dry condition, silica gel is typically blue or light blue. However, it may change color to pink or white when it becomes saturated with moisture.

How often should Silica Gel be replaced?

The frequency of Silica Gel replacement depends on various factors, such as the operating conditions, moisture levels, and size of the Silica Gel Breather. As a general guideline, it is recommended to inspect the silica gel regularly and replace it when it changes color from blue to pink or white, indicating saturation. This typically occurs every 3 to 12 months.

Can Silica Gel Breather be used in other applications?

Yes, silica gel breathers are not limited to transformer applications only. They can be used in various equipment and systems where moisture control is essential, such as electrical panels, switchgear, and storage containers for sensitive items.

Are there any alternatives to Silica Gel Breather?

Yes, there are alternative desiccant materials and breather designs available on the market. Activated alumina, molecular sieves, and permeable membranes are a few alternatives. The application-specific requirements and moisture control requirements determine the desiccant and breather design that should be used.

I have learned something new, actually I didn’t know of Silica Gel Breather, your article has detailed well the features and its use in transformers!