1-What is a Step-Up transformer?

A step-up transformer is a type of electrical transformer that increases the voltage from the input (primary) side to the output (secondary) side. It works on the electromagnetic induction principle, which states that a nearby conductor will become charged when the magnetic field changes.

Two wire coils, referred to as the primary and secondary coils, are wound around a common magnetic core composed of laminated iron or steel to form a step-up transformer. In an input voltage source configuration, the primary coil is connected to the load or output circuit, and the secondary coil is not.

A fluctuating magnetic field surrounds the primary coil when an alternating current (AC) passes through it. Despite the fact that there is no electrical connection between the two coils, the shifting magnetic field causes a voltage to be induced in the secondary coil by mutual induction. The relationship between the secondary coil’s number of turns and the primary coil’s number of turns determines the induced voltage in the secondary coil.

In a step-up transformer, the induced voltage in the secondary coil is larger than the applied voltage in the primary coil because the secondary coil usually has more turns than the primary coil. As a result, the voltage steps up or increases from the transformer’s input side to its output side.

Step-up transformers are frequently employed in a variety of applications, including power transmission, high-voltage power supply, voltage regulation, the integration of renewable energy sources, and industrial processes, where greater voltage levels are necessary. In electrical systems and infrastructure, they are essential for effectively and safely raising voltage levels for distribution, transmission, and use.

2. Components of a Transformer

2.1. Primary Coil:

The transformer’s main coil, which is the initial winding, is where electrical energy is received from the input source, which is usually an AC power supply. This coil is made up of insulated copper wire coiled around a portion of the transformer core a certain number of times. A magnetic field is produced by the alternating current passing through the primary coil.

2.2. Secondary Coil:

The second winding of a transformer, next to the primary coil, is called the secondary coil. Through electromagnetic induction, the main coil’s fluctuating magnetic field causes a voltage to be induced in the secondary coil. The ratio of the secondary coil’s turns to the main coil’s turns determines the induced voltage in the secondary coil.

2.3. Core:

The core of a transformer provides a closed magnetic circuit to guide and concentrate the magnetic flux generated by the primary coil. It is usually made of laminated sheets of high-permeability material such as iron or steel. The laminations help reduce eddy currents and energy losses within the core. The core’s design and material selection are critical for optimizing the transformer’s efficiency and performance.

2.4. Insulation:

Insulation is essential in a transformer to prevent electrical breakdowns and short circuits between the primary and secondary coils, as well as between the coils and the core. Insulating materials such as varnish, enamel, or insulation tapes are used to coat the wire windings and separate them from each other and from the core. Proper insulation ensures the safety and reliability of the transformer, especially when operating at high voltages.

2.5. Terminals:

Wires or cables from external circuits are linked to the primary and secondary coils of the transformer by terminals, which are the external connection points. H1 (high voltage) and H2 (low voltage) are the usual labels for the primary coil terminals, while X1 (high voltage) and X2 (low voltage) are the labels for the secondary coil terminals. Between the transformer and the external circuit, terminals offer a reliable and safe connection for the transfer of electrical energy.

2.6. Tap Changer:

A tap changer is incorporated into certain transformers, particularly those intended for voltage control. The ratio of the input voltage to the output voltage may be changed by adjusting the number of turns in the coils using a tap changer. Even in the event that the input voltage fluctuates, this adjustment aids in maintaining a steady output voltage. Depending on the application and transformer requirements, tap changers can be manually or automatically operated.

Transformers are essential components in a wide range of electrical systems and applications because of these harmonious working parts that facilitate the effective and dependable transmission of electrical energy from the main coil to the secondary coil.

3.How Step-Up Transformers Work

3.1. Principles of Electromagnetic Induction:

Step-up transformers operate based on the principle of electromagnetic induction, which was discovered by Michael Faraday in the 19th century. According to this principle, a changing magnetic field induces an electromotive force (EMF) or voltage in a nearby conductor.

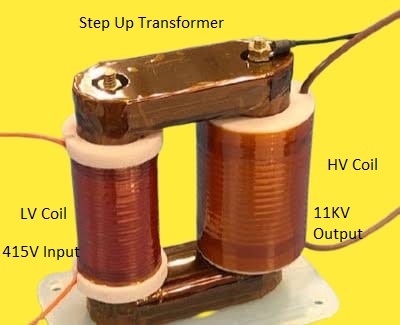

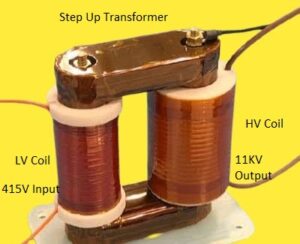

3.2. Construction of a Step-Up Transformer:

A step-up transformer consists of two coils of wire, known as the primary coil and the secondary coil, wound around a common magnetic core made of laminated iron or steel. The primary coil is connected to the input voltage source, while the secondary coil is connected to the load or output circuit.

3.3. Mutual Induction:

When an alternating current (AC) flows through the primary coil, it generates a changing magnetic field around the coil. This changing magnetic field induces a voltage in the secondary coil through mutual induction, even though the two coils are not electrically connected.

3.4. Turns Ratio:

The ratio of the number of turns in the secondary coil to the number of turns in the primary coil determines the voltage transformation ratio of the transformer. In a step-up transformer, the secondary coil has more turns than the primary coil, resulting in a higher output voltage compared to the input voltage.

3.5. Voltage Boosting:

As the alternating current flows through the primary coil, it creates a magnetic flux in the transformer’s core. This changing magnetic flux induces a voltage in the secondary coil according to Faraday’s law of electromagnetic induction. Since the secondary coil has more turns, the induced voltage in the secondary coil is higher than the applied voltage in the primary coil, leading to a step-up or increase in voltage.

3.6. Efficiency and Losses:

Step-up transformers are designed to minimize energy losses and maximize efficiency during voltage transformation. The core material and winding design are optimized to reduce eddy currents and hysteresis losses, ensuring that most of the input energy is transferred to the output side with minimal losses.

3.7. Isolation and Safety:

Step-up transformers provide electrical isolation between the input and output circuits. This isolation helps protect sensitive equipment and ensures safety by preventing direct electrical contact between different parts of the electrical system.

3.8. Applications:

Step-up transformers are used in various applications where higher voltages are required, such as power transmission and distribution, high-voltage power supplies for industrial processes, and electronic devices that operate at higher voltages.

4-Construction and Design

4.1. Core Material:

High-permeability materials, such as silicon steel or iron, are laminated to create the core of transformers. In order to avoid eddy currents, which can result in energy losses and heat accumulation inside the core, these laminations are isolated from one another. The magnetic flux produced by the coils has a low-reluctance route through the core.

4.2. Coil Windings:

The main winding and the secondary winding are the two sets of coil windings found in transformers. While the secondary winding is linked to the load or output circuit, the main winding is connected to the input voltage source. Copper wire, which has a high conductivity and low resistance to electrical current, is usually used for both windings.

4.3. Turns Ratio:

The transformer’s voltage transformation ratio is based on the turns ratio between its primary and secondary windings. A step-up transformer produces an output voltage that is greater than the input voltage because the secondary winding has more turns than the main winding. The number of turns in each winding and the intended voltage transformation are used to compute the turns ratio.

4.4 Insulation:

To avoid electrical failure and short circuits between the windings and the core, insulation is essential. The wire windings are coated with insulating materials, such as varnish, enamel, or insulation tapes, which keep them apart from the core and from one another. When working at high voltages, the transformer’s dependability and safety are guaranteed by proper insulation.

4.5. Cooling System:

The losses in the core and windings of transformers cause them to produce heat while they are operating. Transformers are fitted with cooling systems, such as oil or air cooling, to disperse this heat and maintain ideal working temperatures. Transformer oil is used as a coolant in oil-filled transformers, moving through the windings and core to absorb heat and send it to radiators or external cooling fins. Air-cooled transformers use forced or natural airflow to release heat.

4.6. Tap Changer:

Tap changers are a feature of several transformers, particularly some step-up transformers. The output voltage may be changed by adjusting the number of turns in the coils with the use of a tap changer. This capability is very helpful for controlling voltage and adjusting to different load scenarios.

4.7. Enclosure and Protection:

To safeguard transformers against mechanical damage and environmental elements, they are contained in enclosures composed of sturdy materials like steel or aluminum. In order to defend against overloads, short circuits, and lightning strikes, they could also have safety features like fuses, circuit breakers, and surge arrestors installed.

4.8. Efficiency and Design Optimization:

To increase efficiency, lower losses, and boost reliability, transformer designs are continuously refined. To optimize performance while reducing operational costs and environmental effect, factors including cooling system design, insulation quality, winding arrangement, and core material selection are carefully taken into account.

5-Applications of Step-Up Transformers

Step-up transformers are used in many important applications across a range of sectors and industries. Here is a thorough examination of some of the most important uses for step-up transformers:

5.1. Transmission of Power:

Power transmission systems are one of the main uses for step-up transformers. In order to reach customers, electricity produced by power plants is usually carried over great distances. To raise the voltage of energy produced by power plants to levels appropriate for effective long-distance transmission, step-up transformers are employed. Increased voltages lower transmission losses and enable the use of lighter, thinner transmission lines, which save money and increase efficiency.

5.2. High-Voltage Power Supplies:

A vital part of high-voltage power supplies used in a range of scientific and industrial applications are step-up transformers. Particle accelerators, X-ray machines, and some industrial equipment, for example, need high-voltage power sources in order to function properly. To raise the voltage to the required levels for various applications, step-up transformers are essential for dependable operation and precise outcomes.

5.3. Voltage Regulation:

To stabilize and modify the voltage levels in electrical grids and distribution networks, voltage regulation systems employ step-up transformers. These transformers assist in maintaining constant voltage levels even during times of high demand or variable loads by increasing the voltage as necessary. In addition to ensuring that electrical equipment operates as intended, voltage regulation guards against problems caused by variations, surges, and sags in voltage.

5.4. Integration of Renewable Energy:

Step-up transformers are essential for incorporating solar and wind energy into the electrical system. The voltage levels of electricity generated by renewable energy sources must be increased to correspond with the grid’s voltage levels in order to ensure effective distribution and transmission. Step-up transformers facilitate the smooth integration of renewable energy sources into the current electrical infrastructure, hence aiding in the shift towards more sustainable and environmentally friendly energy sources.

5.5. Electrical Distribution:

To provide energy to customers in homes, businesses, and industries, step-up transformers are employed in electrical distribution systems. The high-voltage energy carried by power lines is reduced by these transformers to safer, lower voltage levels appropriate for usage in residences, commercial buildings, and industrial sites. The effective and dependable delivery of power to end customers is facilitated by step-up transformers found in substations and distribution centers.

5.6. Railway Electrification:

To power electric trains and engines, railway electrification systems use step-up transformers. These transformers raise the power from the third rails or overhead catenary wires to the levels needed by the traction motors of the trains. Step-up transformers, which supply high-voltage power to electric trains, allow them to run more consistently and effectively, lowering emissions and enhancing the sustainability of transportation.

7-Advantages of Step-Up Transformers

Step-up transformers have several benefits for a range of electrical uses. The following are some of step-up transformers’ main benefits:

7.1. Effective Voltage Transformation:

The voltage levels from the main winding to the secondary winding are effectively increased using step-up transformers. It is possible to transmit electrical power over great distances with little energy loss because to its capacity to scale up voltage. Elevated voltages enhance transmission efficiency by decreasing the current passing via transmission lines, which in turn minimizes resistive losses.

7.2. Enhanced Power Transmission:

Step-up transformers allow for the effective transfer of electrical power across transmission lines and grids by raising the voltage levels. High-voltage transmission makes long-distance distribution of significant amounts of power possible while reducing the requirement for substantial infrastructure. Because of this, step-up transformers are crucial parts of power transmission networks that allow customers to have a steady supply of electricity.

7.3. Compact and Lightweight Design:

Step-up transformers are made with an effective voltage transition in mind, all while maintaining a compact and lightweight design. Because of its small size, this design is simple to install and integrate into the current infrastructure and electrical systems. Step-up transformers’ lightweight design makes handling and installation easier and saves money on shipping.

7.4. Voltage Regulation Capability:

Step-up transformers may also act as voltage regulators, making sure that, in the face of fluctuating load circumstances, the output voltage stays within predetermined bounds. Electrical systems require voltage control to be stable and reliable, particularly during times of high demand or variable loads. Step-up transformers aid in maintaining steady power supply by reducing voltage swings and stabilizing voltage levels.

7.5. Broad Application:

Power generation, transmission, distribution, industrial operations, and the integration of renewable energy sources are just a few of the industries and areas in which step-up transformers find use. Because of their adaptability and versatility, they are essential parts of a wide range of electrical systems and infrastructure, meeting a wide range of needs and applications.

7.6. Better Performance and Efficiency:

Step-up transformers are made to work as efficiently as possible, transferring the maximum amount of electrical power from the main winding to the secondary winding while minimizing energy losses. During the transformer’s operating lifespan, this increased efficiency saves money and has a smaller negative impact on the environment. Furthermore, effective voltage transformation improves the dependability and performance of electrical systems, guaranteeing a steady supply of power and optimal system functioning.

8-Disadvantages of Step-Up Transformer

While step-up transformers offer various advantages, they also come with certain disadvantages and challenges. Here are some of the key disadvantages of step-up transformers:

8.1. Complex Design and Construction:

Step-up transformers tend to have a more complex design and construction compared to simpler transformers. The need for precise winding ratios, insulation requirements, and core materials increases manufacturing complexity and costs. Additionally, the complexity of the design may lead to higher maintenance and repair expenses over time.

8.2. Higher Initial Cost:

The initial cost of purchasing and installing step-up transformers can be relatively high compared to other types of transformers. This is partly due to the specialized design and construction required to achieve efficient voltage transformation and reliable operation. The higher initial investment may pose a barrier to adoption, particularly for smaller-scale applications or projects with budget constraints.

8.3. Maintenance Requirements:

Step-up transformers require regular inspection, maintenance, and testing to ensure optimal performance and reliability. Issues such as insulation degradation, winding faults, and core deterioration can occur over time, leading to potential downtime and operational disruptions if not addressed promptly. Maintenance tasks may involve specialized equipment and skilled personnel, adding to operational expenses and complexity.

8.4. Increased Risk of Electrical Hazards:

Step-up transformers operate at high voltages, posing a greater risk of electrical hazards such as shock, arc flash, and insulation breakdown. Safety measures must be strictly followed during installation, operation, and maintenance to mitigate these risks and ensure the safety of personnel and equipment. Adequate training, protective equipment, and safety protocols are essential to minimize the likelihood of accidents and injuries.

8.5. Limited Flexibility in Voltage Regulation:

While step-up transformers can increase voltage levels efficiently, they may offer limited flexibility in voltage regulation compared to other types of transformers. Voltage regulation capabilities may be constrained by the fixed turns ratio and design parameters of the transformer. As a result, achieving precise voltage control and adjustment under varying load conditions may require additional equipment or complex control systems.

8.6. Environmental Impact:

The manufacturing, operation, and disposal of step-up transformers can have environmental implications, including energy consumption, resource utilization, and waste generation. Materials used in transformer construction, such as copper, steel, and insulation materials, may have environmental footprints associated with extraction, processing, and disposal. Efforts to minimize environmental impact, such as energy-efficient designs, recycling initiatives, and eco-friendly materials, are important considerations in transformer development and operation.

9-Safety Considerations

Given the high voltages involved, proper insulation and safety measures are crucial when working with step-up transformers to prevent electrical hazards and accidents.

10-Maintenance and Care

Regular inspection and maintenance routines are essential to ensure the longevity and efficiency of step-up transformers. This includes checking for insulation degradation, loose connections, and overheating.

11-Importance in Various Industries

The role of step-up transformers extends across multiple industries, ranging from power generation and distribution to telecommunications and healthcare.

12-Future Trends and Innovations

Advancements in transformer technology aim to improve efficiency, reduce losses, and enhance reliability. Innovations such as solid-state transformers and smart grid integration are paving the way for a more sustainable and interconnected electrical infrastructure.

13-Conclusion

In conclusion, step-up transformers play a pivotal role in modern electrical systems, facilitating efficient voltage transformation, power transmission, and distribution across various industries and applications. Despite their advantages in increasing voltage levels and enabling long-distance power transmission, step-up transformers also come with certain challenges and limitations.

The complexity of their design and construction, coupled with higher initial costs and maintenance requirements, underscores the need for careful planning and investment in transformer infrastructure. Additionally, the inherent risks of electrical hazards and limited flexibility in voltage regulation necessitate stringent safety measures and effective control systems to ensure reliable and safe operation.

However, the benefits of step-up transformers, including enhanced power transmission capabilities, improved efficiency, and flexibility in voltage transformation, outweigh their disadvantages in many cases. With proper design, installation, and maintenance practices, step-up transformers can continue to serve as critical components in supporting reliable and sustainable electrical infrastructure worldwide.

As technology advances and energy demands evolve, ongoing innovation and development in transformer design, materials, and efficiency will further enhance the performance and reliability of step-up transformers, contributing to the continued advancement of electrical engineering and power distribution systems.

14-FAQs (Frequently Asked Questions)

What is the main function of a step up transformer?

Increasing the voltage from the input side (primary winding) to the output side (secondary winding) is the principal purpose of a step-up transformer. It accomplishes this by applying a voltage greater than that to the primary winding in the secondary winding through the use of electromagnetic induction. Step-up transformers are frequently employed in a variety of applications where greater voltage levels are necessary for effective operation, such as power transmission, high-voltage power supply, voltage control, and the integration of renewable energy sources.

Is step up transformer AC or DC?

Similar to other transformers, a step-up transformer runs on alternating current (AC) power. Transformers operate with AC electricity thanks to the principles of electromagnetic induction. A step-up transformer’s secondary winding experiences a voltage as a result of the shifting magnetic field produced by the AC current flowing through the primary winding. Next, the primary side of the transformer’s induced voltage is raised or stepped up to the secondary side. Consequently, direct current (DC) circuits are not commonly utilized with step-up transformers as they are intended to operate with AC power.

Which transformer converts AC to DC?

Direct current (DC) is not produced by the transformer itself; alternating current (AC) is. To convert AC to DC, rectifiers are often used in combination with transformers. Rectifiers are electrical devices that allow current to flow in a single direction only in order to convert AC voltage to DC voltage.

Transformers are used to step down the voltage from the power grid in some applications, such as power supplies for electronic devices or rectifier substations for power distribution. Rectifiers are then used to convert the AC voltage to DC voltage suitable for use in various electronic devices or systems.

Therefore, rectifiers are what truly convert AC to DC, even if transformers also help to step down (or occasionally boost) the voltage.

Leave a Reply