1. Introduction to Sweep Frequency Response Analysis (SFRA) Test

Transformers play a crucial role in electrical power systems by facilitating electricity’s efficient transmission and distribution. However, transformers may experience various faults and defects over time due to aging, environmental conditions, or manufacturing issues. To ensure the reliability and performance of transformers, utilities and industries utilize diagnostic tests such as Sweep Frequency Response Analysis (SFRA).

1.1 What is the SFRA Test?

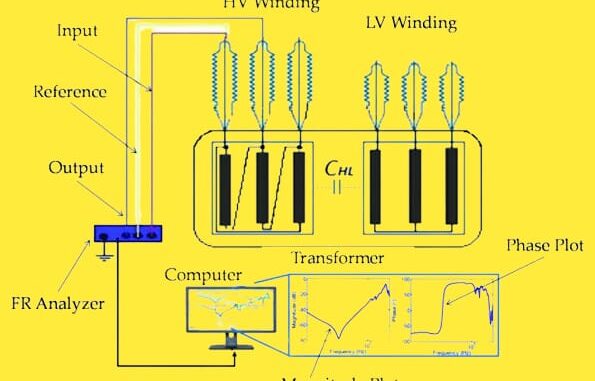

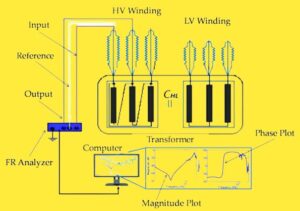

Sweep Frequency Response Analysis (SFRA) is a diagnostic test used to assess the mechanical integrity and winding condition of transformers. During an SFRA test, a sinusoidal signal is injected into the transformer windings across a range of frequencies. The response of the transformer to these frequencies is measured and plotted on a graph known as an SFRA plot.

The SFRA plot typically displays magnitude and phase angle information, allowing technicians to identify abnormalities in the transformer’s frequency response. Any deviations from the expected response curve may indicate potential defects or structural issues within the transformer.

SFRA testing is a non-invasive technique that can detect a wide range of transformer faults, including shorted turns, winding displacement, core movement, and insulation degradation. Early detection of these issues allows for proactive maintenance and prevents costly downtime and equipment failures.

By analyzing SFRA test results, technicians can pinpoint the location and severity of potential faults within the transformer, facilitating timely intervention and ensuring the continued reliability and performance of the transformer. SFRA testing is widely used in the maintenance and diagnostics of transformers in various industrial and utility applications.

2. Importance of SFRA Test in Transformer Maintenance

The SFRA test is a powerful diagnostic tool used to assess transformers’ mechanical integrity and winding condition. It involves applying a range of frequencies to the transformer windings and analyzing the resulting frequency response. Any deviations from the expected response can indicate potential defects or structural issues within the transformer.

3. The procedure of the SFRA Test

The procedure of the Sweep Frequency Response Analysis (SFRA) test involves several key steps:

- Preparation: Before conducting the SFRA test, ensure the transformer is de-energized and disconnected from the power source. Follow all safety protocols and obtain the necessary permits or approvals for testing.

- Setup: Set up the SFRA test equipment, including the test instrument, cables, and probes. Ensure all connections are secure and properly configured according to the manufacturer’s guidelines.

- Calibration: Calibrate the SFRA test instrument to ensure accurate measurements. Verify the functionality of the equipment and perform any necessary adjustments or corrections.

- Excitation Signal: Apply a sinusoidal excitation signal to the transformer windings across various frequencies. The excitation signal should cover a broad frequency spectrum to accurately capture the transformer’s response.

- Measurement: Measure the response of the transformer to the excitation signal at each frequency point. Record both the magnitude and phase angle of the response for analysis.

- Data Collection: Collect data from the SFRA test instrument and store it for further analysis. Ensure the data is organized and properly labeled to facilitate interpretation and comparison.

- Analysis: Analyze the SFRA data to identify deviations or anomalies in the transformer’s frequency response. Compare the measured response with reference data or standard response curves to assess the transformer’s condition.

- Interpretation: Interpret the SFRA test results based on established criteria and guidelines. Look for patterns or trends in the data that may indicate potential faults or defects within the transformer windings.

- Reporting: Prepare a comprehensive report detailing the SFRA test procedure, results, and findings. Include any recommendations for further investigation or corrective action based on the analysis.

- Review: Review the SFRA test results with relevant stakeholders, such as maintenance personnel or engineering teams. Discuss any identified issues and develop a plan for addressing them effectively.

4. Interpretation of SFRA Test Results

Interpreting Sweep Frequency Response Analysis (SFRA) test results involves analyzing the data obtained during the test to evaluate the condition of a transformer’s windings and to detect any potential faults or abnormalities. This process includes comparing the measured SFRA response of the power and distribution transformers with established reference data or standard response curves for similar transformers.

By examining the magnitude and phase angle of the SFRA response across the frequency spectrum, technicians can identify significant changes that may indicate the presence of faults, such as winding deformation, mechanical damage, or core displacement. Additionally, technicians look for patterns or trends in the SFRA data that could reveal specific types of faults within the transformer. Correlating SFRA results with findings from other diagnostic tests provides a more comprehensive understanding of the transformer’s condition and helps validate the accuracy of the SFRA analysis.

Expert judgment and experience play a crucial role in interpreting SFRA test results, as experienced technicians leverage their knowledge of transformer behavior and failure modes to make informed assessments and recommendations for maintenance or further analysis. Clear documentation and reporting of the interpretation findings are essential for communicating the results to relevant stakeholders and guiding decision-making processes regarding transformer maintenance and reliability.

5. Common Issues Detected by SFRA Test

The SFRA test can detect various common issues in transformers, providing crucial insights into their health and condition. Some typical issues the SFRA test seen include shorted turns, winding displacement, core movement, and insulation degradation.

- Shorted Turns: Shorted turns occur when the insulation between turns in the transformer winding breaks down, decreasing the impedance of the affected winding. SFRA testing can detect changes in impedance across the frequency spectrum, indicating the presence of shorted turns.

- Winding Displacement: Winding displacement refers to the movement or shifting of the transformer windings from their original positions. This displacement can result from mechanical stress, thermal expansion, or other external factors. SFRA testing can identify abnormalities in the frequency response caused by winding displacement, helping to pinpoint the location and extent of the displacement.

- Core Movement: Core movement occurs when the transformer core shifts or becomes misaligned, affecting the transformer’s magnetic flux distribution and overall performance. SFRA testing can detect changes in the frequency response associated with core movement, providing early warning signs of potential issues.

- Insulation Degradation: Insulation degradation is a common problem in transformers, resulting from thermal stress, moisture ingress, or chemical degradation. SFRA testing can reveal changes in the frequency response caused by insulation degradation, helping to assess the overall condition of the transformer insulation system.

6. Advantages of SFRA Testing

One of the primary advantages of SFRA testing is its ability to detect internal transformer faults non-invasively. Unlike traditional diagnostic methods that require de-energizing the transformer and conducting physical inspections, SFRA testing can be performed without disrupting normal operations.

7. Limitations of SFRA Testing

While SFRA testing is highly effective, it does have limitations. Interpreting SFRA results requires expertise and experience, and false positives or false negatives can occur if the test is not conducted correctly or if environmental conditions impact the measurements.

8. Comparison with Other Transformer Diagnostic Tests

SFRA testing complements other diagnostic techniques, such as insulation resistance testing, dissolved gas analysis, and partial discharge monitoring. Each test provides unique insights into transformer health, and combining multiple diagnostic methods enhances overall reliability and accuracy.

9. Best Practices for Conducting SFRA Tests

To ensure accurate and reliable results, following best practices when conducting SFRA tests is essential. This includes proper instrument calibration, careful test setup, and adherence to industry standards and guidelines.

10. Case Studies and Examples

Several real-world examples demonstrate the effectiveness of SFRA testing in identifying and diagnosing transformer faults. Case studies highlight the importance of proactive maintenance and the role of SFRA testing in preventing catastrophic failures.

11. Future Trends in Transformer Testing

As technology advances, transformer testing techniques continue to evolve. Future trends include the integration of artificial intelligence and machine learning algorithms for predictive maintenance and enhanced diagnostic capabilities.

12. Conclusion

In conclusion, Sweep Frequency Response Analysis (SFRA) testing is a valuable tool for assessing transformers’ mechanical integrity and winding condition. By analyzing the frequency response of transformers, technicians can identify potential faults and take proactive measures to ensure reliable operation and prevent costly downtime.

13. Frequently Asked Questions (FAQs)

What is SFRA testing, and how does it work?

SFRA testing is a diagnostic technique used to assess transformers’ mechanical integrity and winding condition. It involves applying a range of frequencies to the transformer windings and analyzing the resulting frequency response.

Why is SFRA testing essential for transformer maintenance?

SFRA testing helps detect potential faults and defects within transformers, allowing for proactive maintenance and preventing costly downtime and equipment failures.

What are some common issues detected by SFRA testing?

SFRA testing can detect shorted turns, winding displacement, core movement, and insulation degradation.

How does SFRA testing compare to other diagnostic tests for transformers?

SFRA testing complements other diagnostic techniques and provides unique insights into transformer health, enhancing overall reliability and accuracy.

What are the best practices for conducting SFRA tests?

Best practices include proper instrument calibration, careful test setup, and adherence to industry standards and guidelines.

Leave a Reply